Dual Spindle CNC Lathe

DS-36B

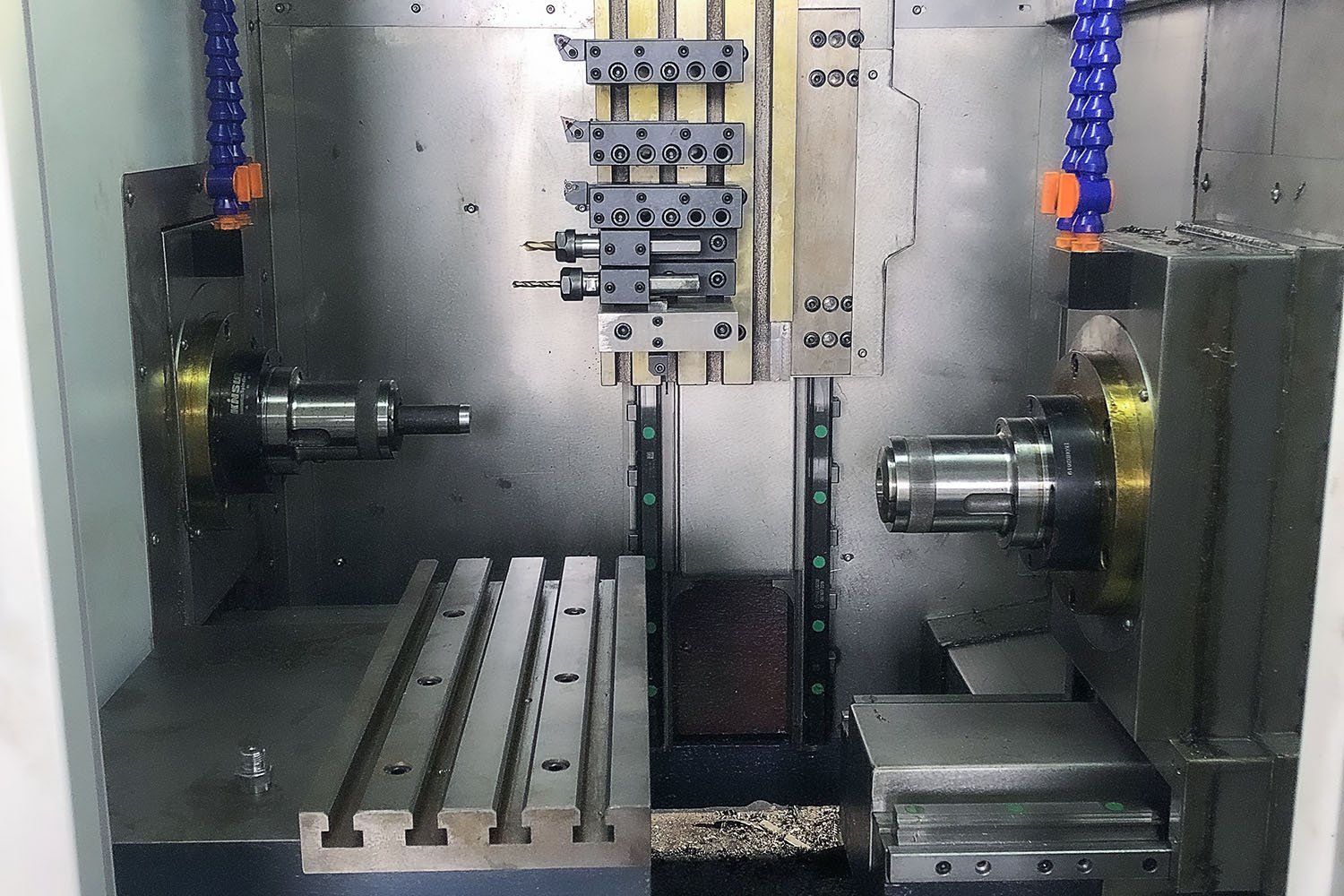

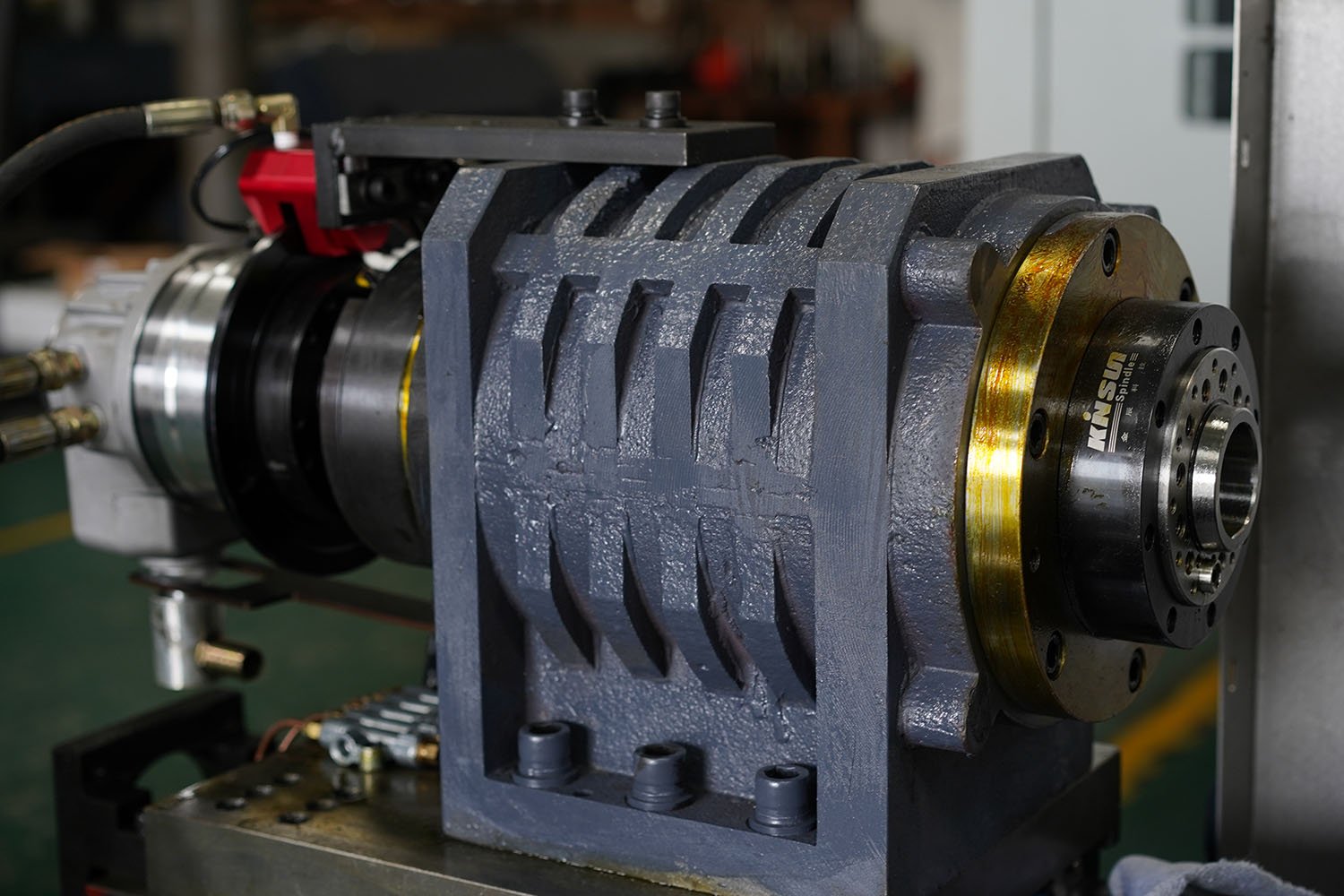

Manually moving the same part with two ends between machines for various processing can lengthen setup times, raise manpower costs, and decrease part accuracy. Machine shops must raise output and accuracy to bolster their bottom line as the manufacturing sector deals with a skilled labor scarcity and a slowing economy. Double-ended parts can be turned on a single machine using the DS-36B dual-spindle lathe, which is user-friendly for the bar materials.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

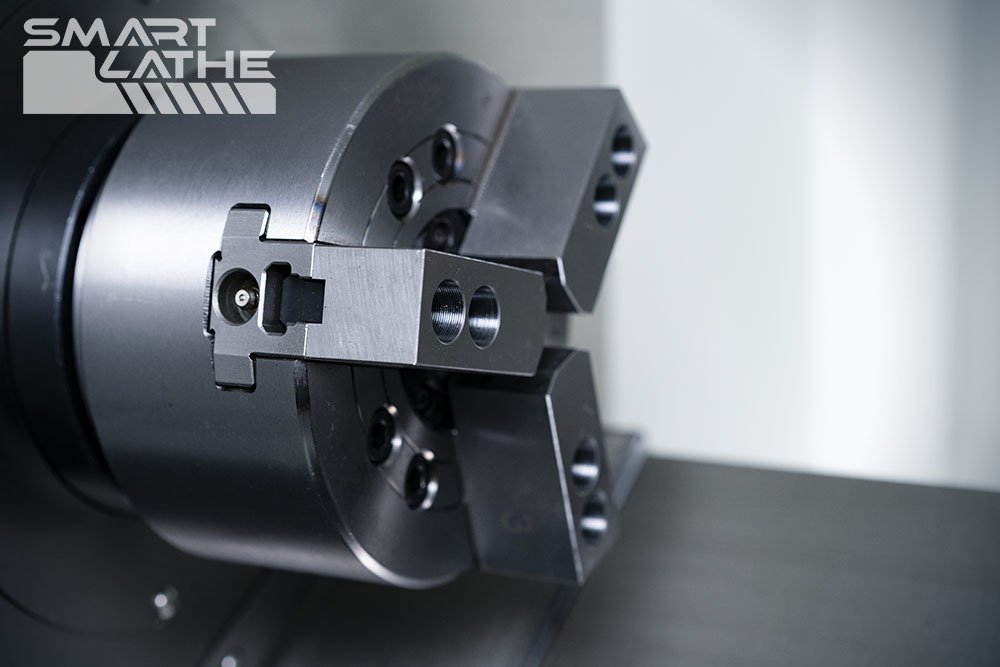

| Optional | ||||||

3 Jaws Chuck

Auto bar feeder |

||||||

Application

This multi-tasking dual spindle turning center is an advanced model designed to process precision complex parts in one setup, which could operate the turning process of double-ended parts in a single setup with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with single workpieces up to φ100mm and Bar Material up to φ35mm. This DS-36B model is a Swiss-type CNC dual spindle lathe specialized for the highly efficient and automatic turning of bar materials.

Case Study

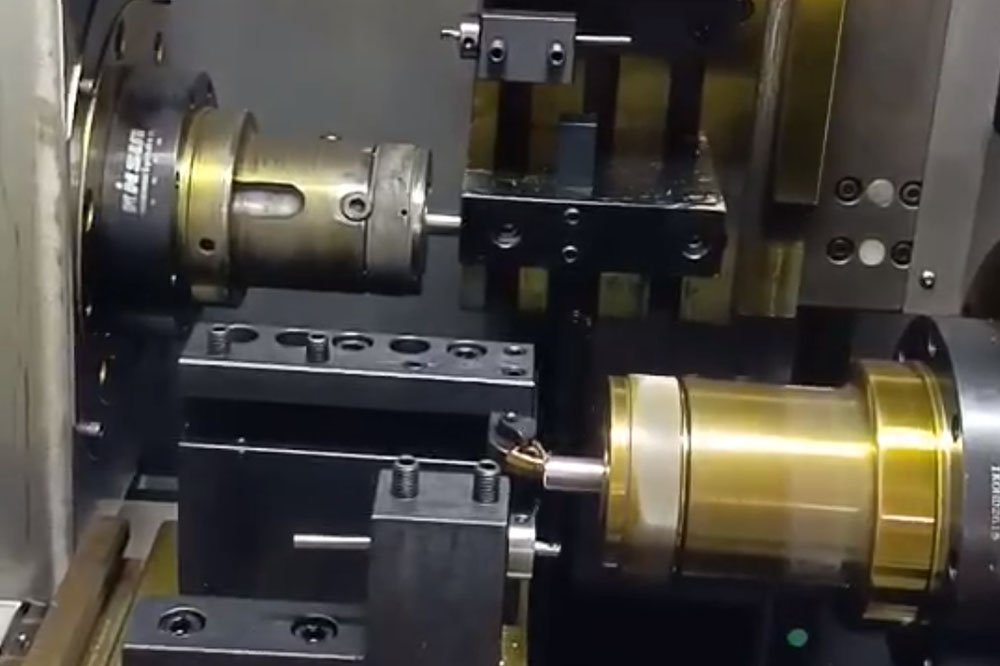

Configuration: DS-36B installs the Hydraulic collect, Bar feeder, Gang type tools

Workpiece: Φ16*1.5 stainless steel seamless pipe

Machining Process: Turning, Drilling, Tapping.

Turning Duration: within 25 seconds one-time processing