Smart CNC Lathe

SL-X

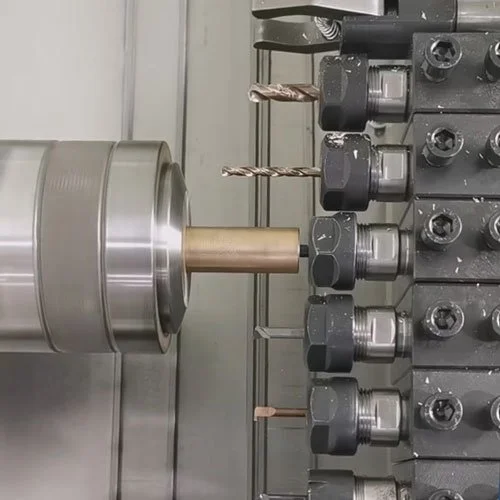

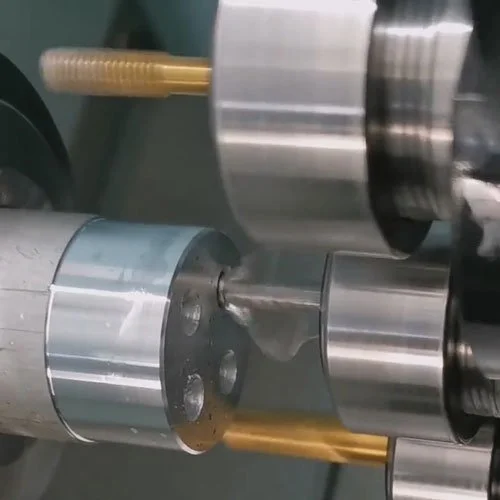

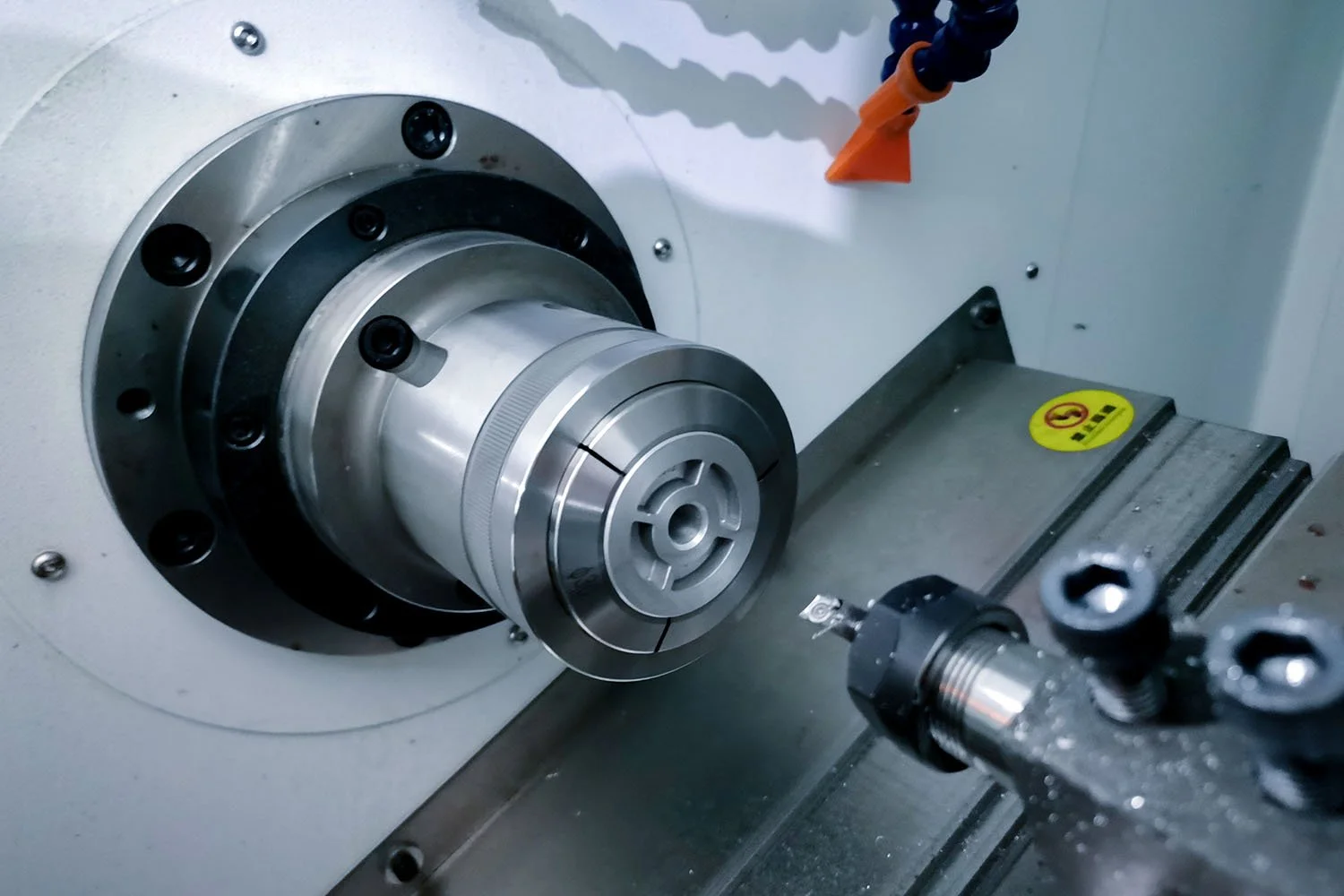

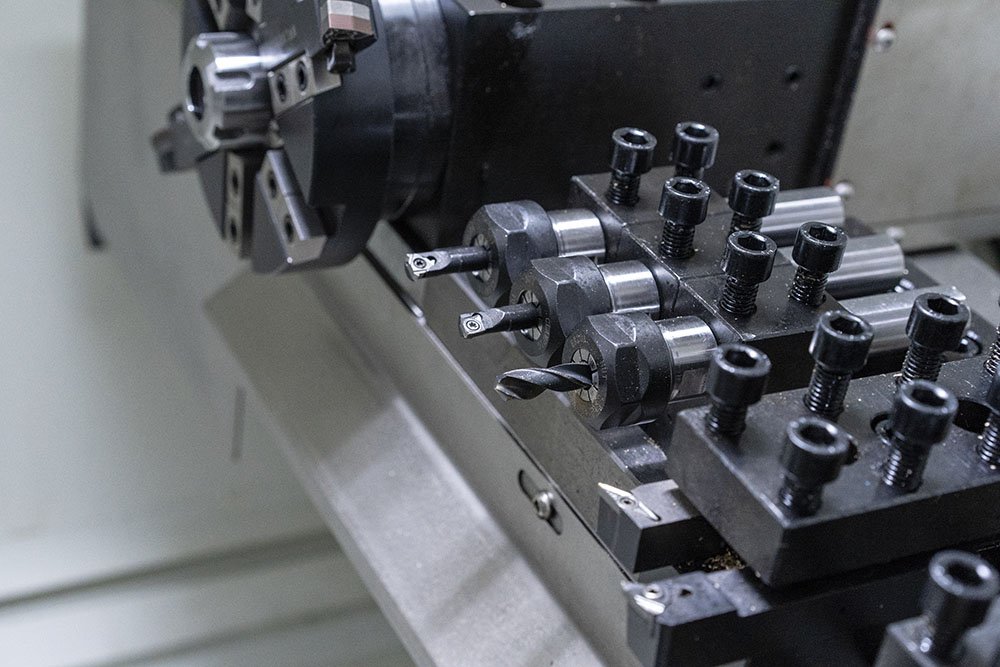

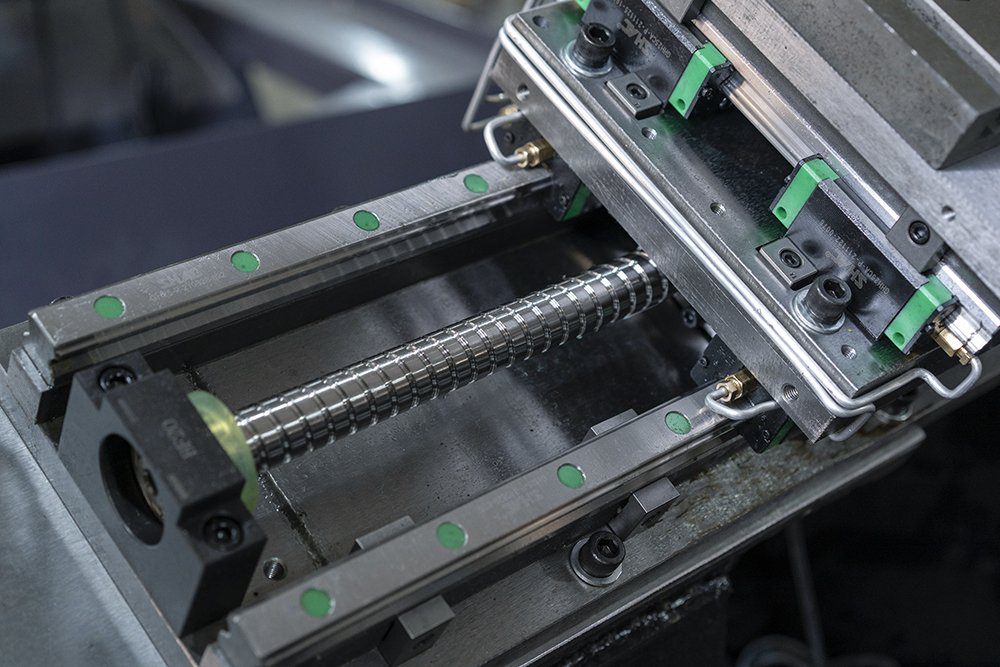

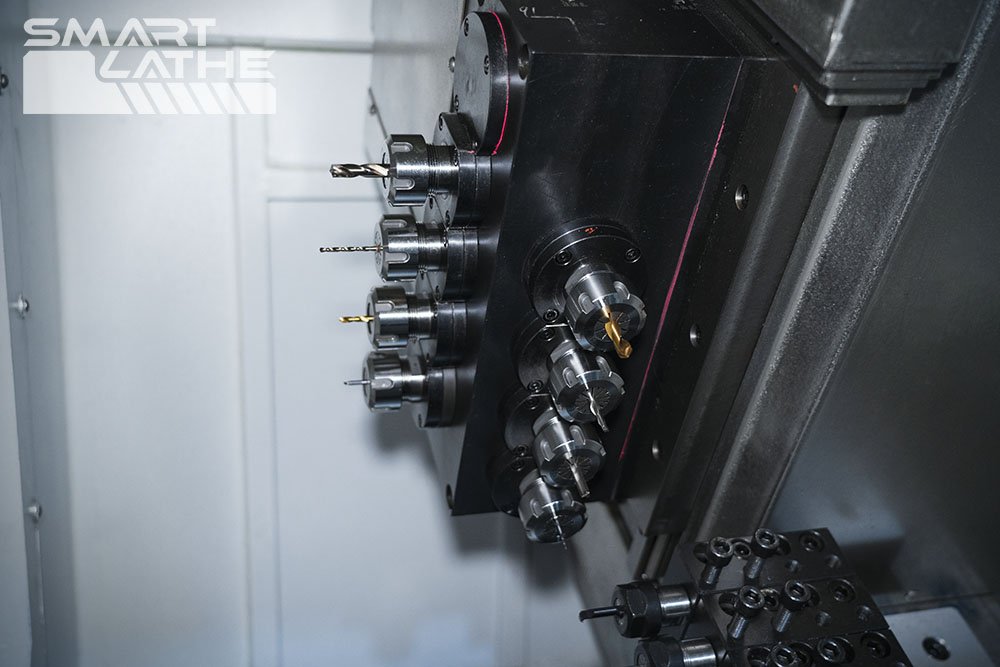

The SL-X is a CNC turning and milling machine that provides various possibilities of tooling combinations with a more powerful spindle (7.4 HP). It is the best solution to satisfy the diverse demand for metalworking and the goal to minimize the tool change time.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

Servo Bar Feeder

Oil Bar Feeder

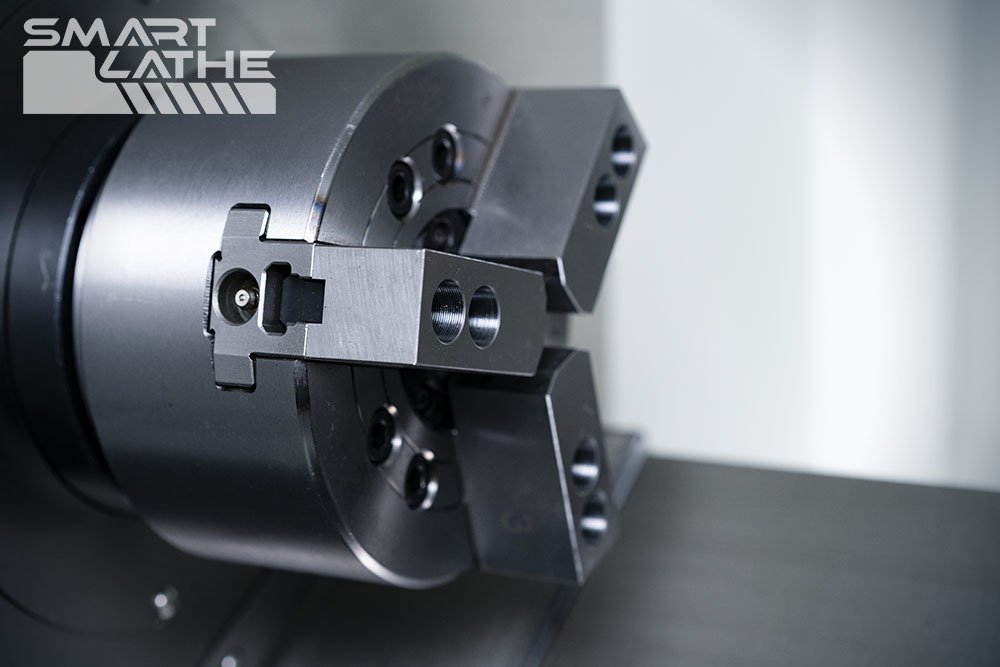

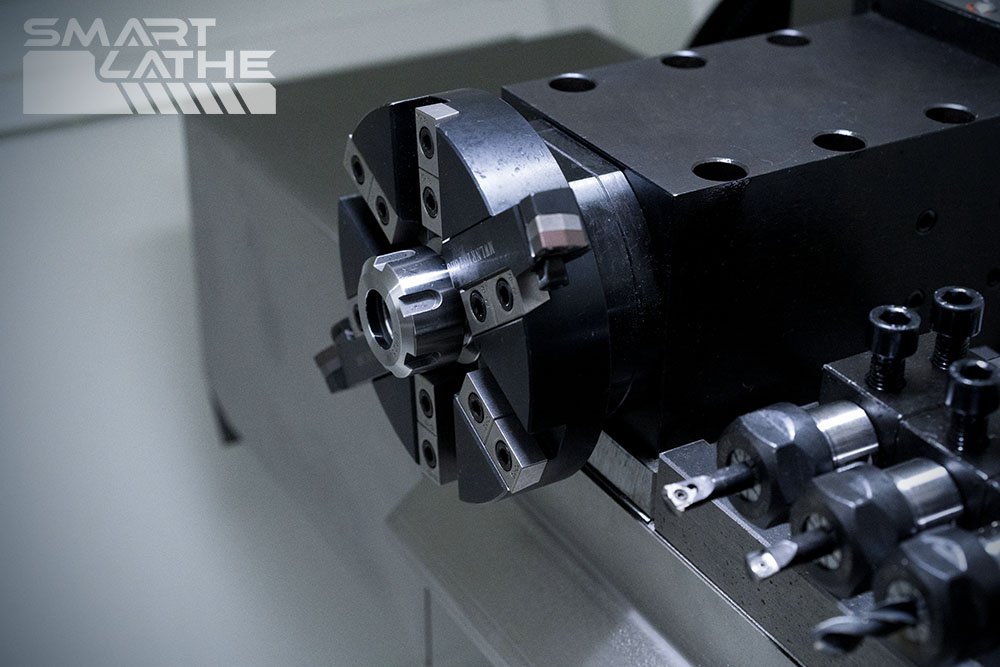

3 Jaws Chuck

Step Type Live Tool

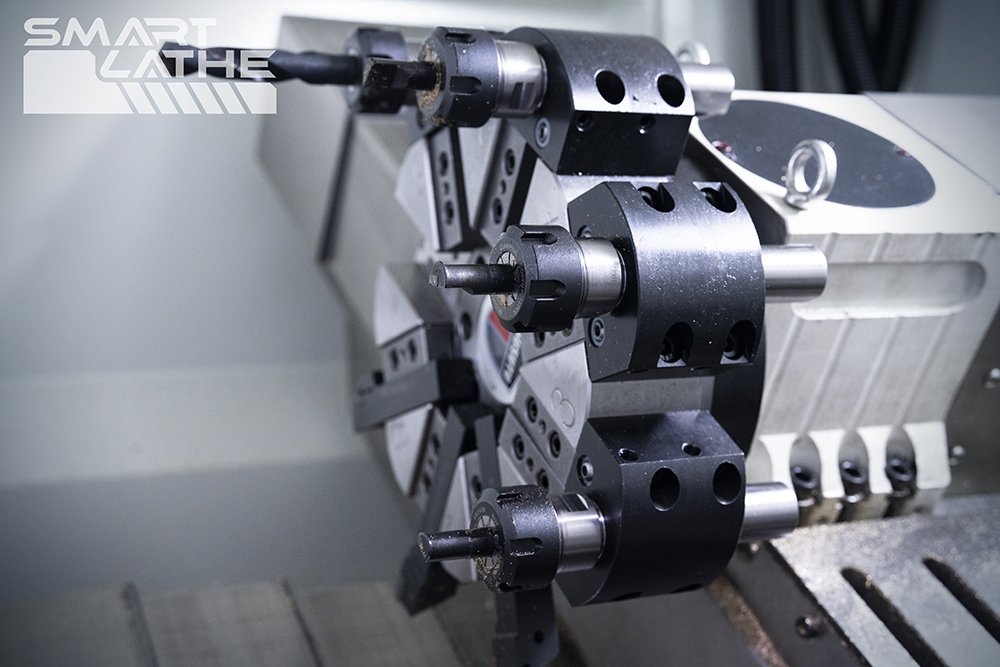

Servo Turret

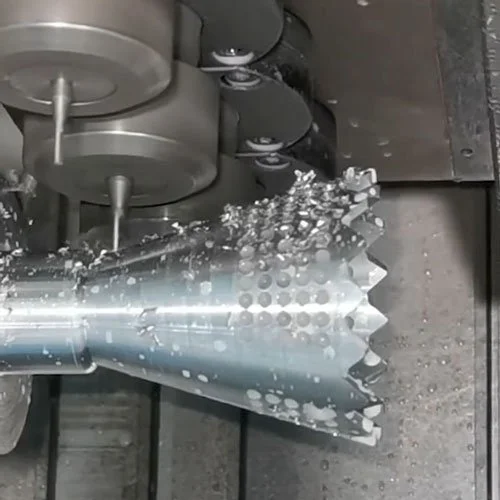

Polygon Milling

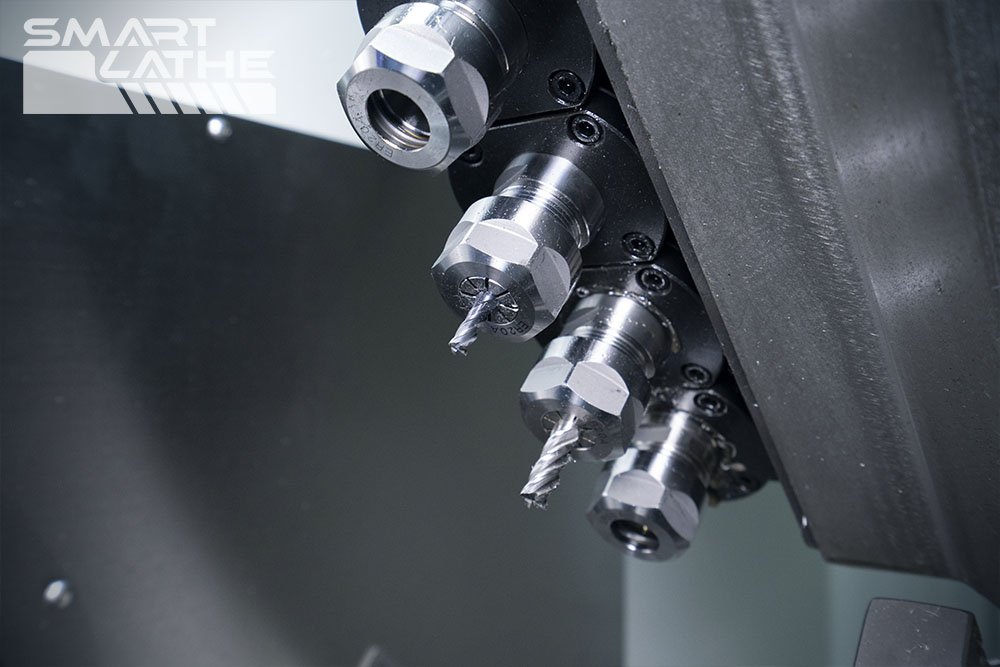

4 Shaft Live Tools

8 Live Tooling Device |

||||||

Application

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to Φ46 mm or single workpieces up to Φ50mm.