Introduction of CNC Lathe

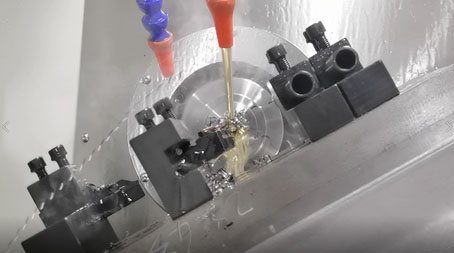

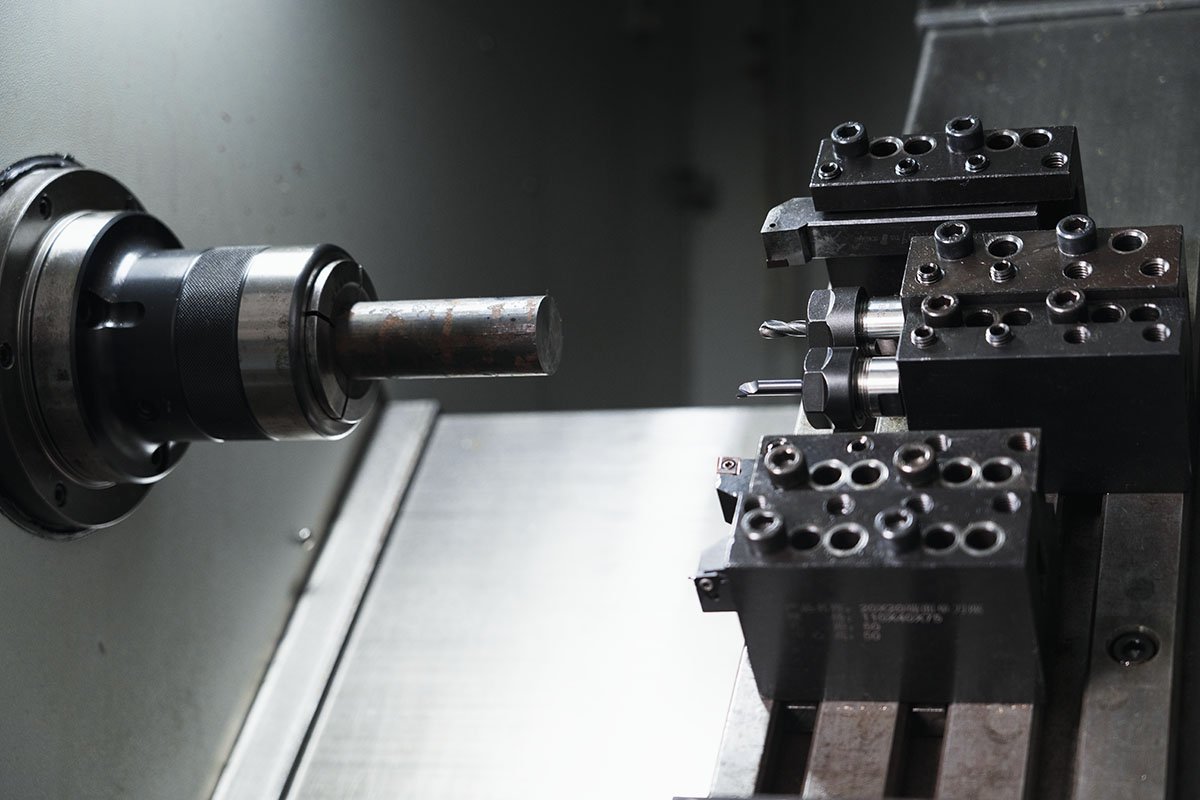

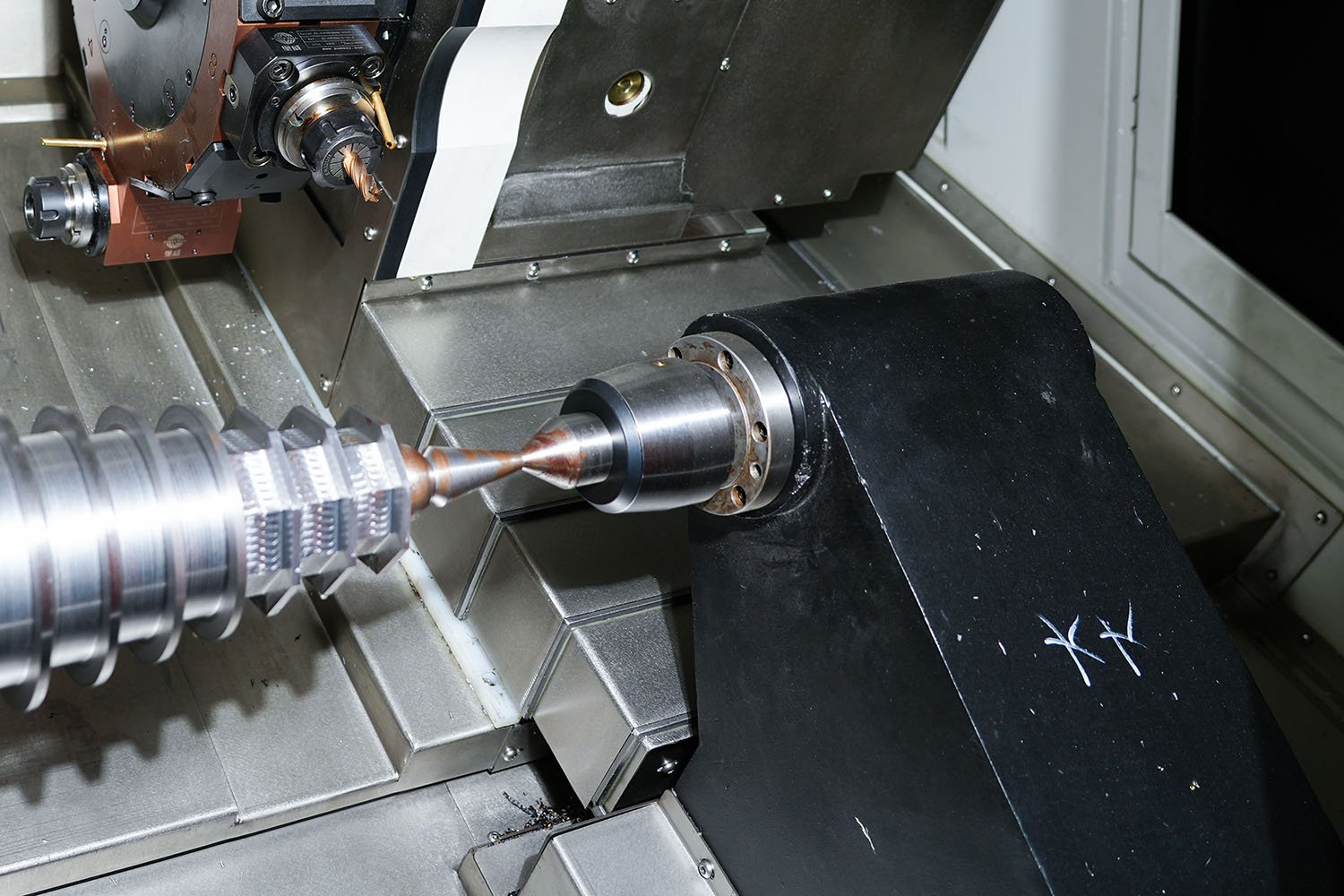

CNC lathe is a computer-numeric controlled machine tool specialized in CNC turning machining, including taper turning, hard turning, spherical generation, facing, cutting off, knurling, drilling, grooving, etc. Compared to a conventional lathe, CNC lathes are operated with precise design instructions and programs to improve the productivity and precision of CNC machining demands.

What are the operations performed in a CNC lathe?

Obviously, CNC lathe is the most popular Lathes on the market, and let’ study more about it. CNC means Computerized numerically controlled, which is widely used as a lathe in modern society because of its fast and accurate working.

Lathe Spindle Nose Identification Chart

To establish the type of spindle nose you have, look through the diagrams below. Make the necessary measurements after analyzing the related chart. For your chuck or adapter plate, choose the spindle nose size.

What is the difference between Swiss type and Fixed type CNC lathe

A Swiss CNC machine, also known as a Swiss type lathe or a Swiss automatic lathe, is a sophisticated precision manufacturing machine capable of quickly and correctly producing exceedingly small parts. Belong to the precision processing equipment, also has a turning, milling, drilling, tapping, boring, carving, etc.

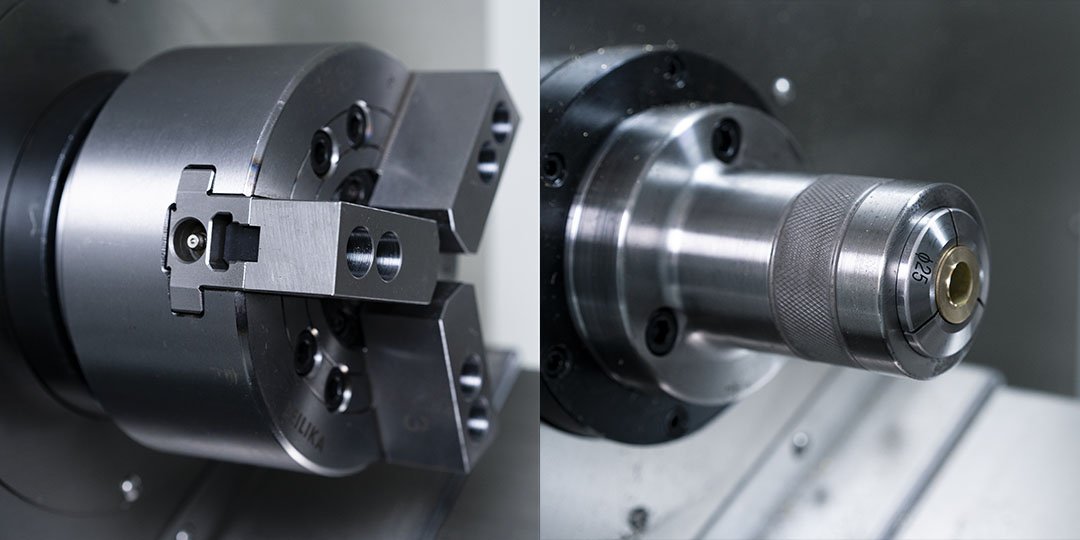

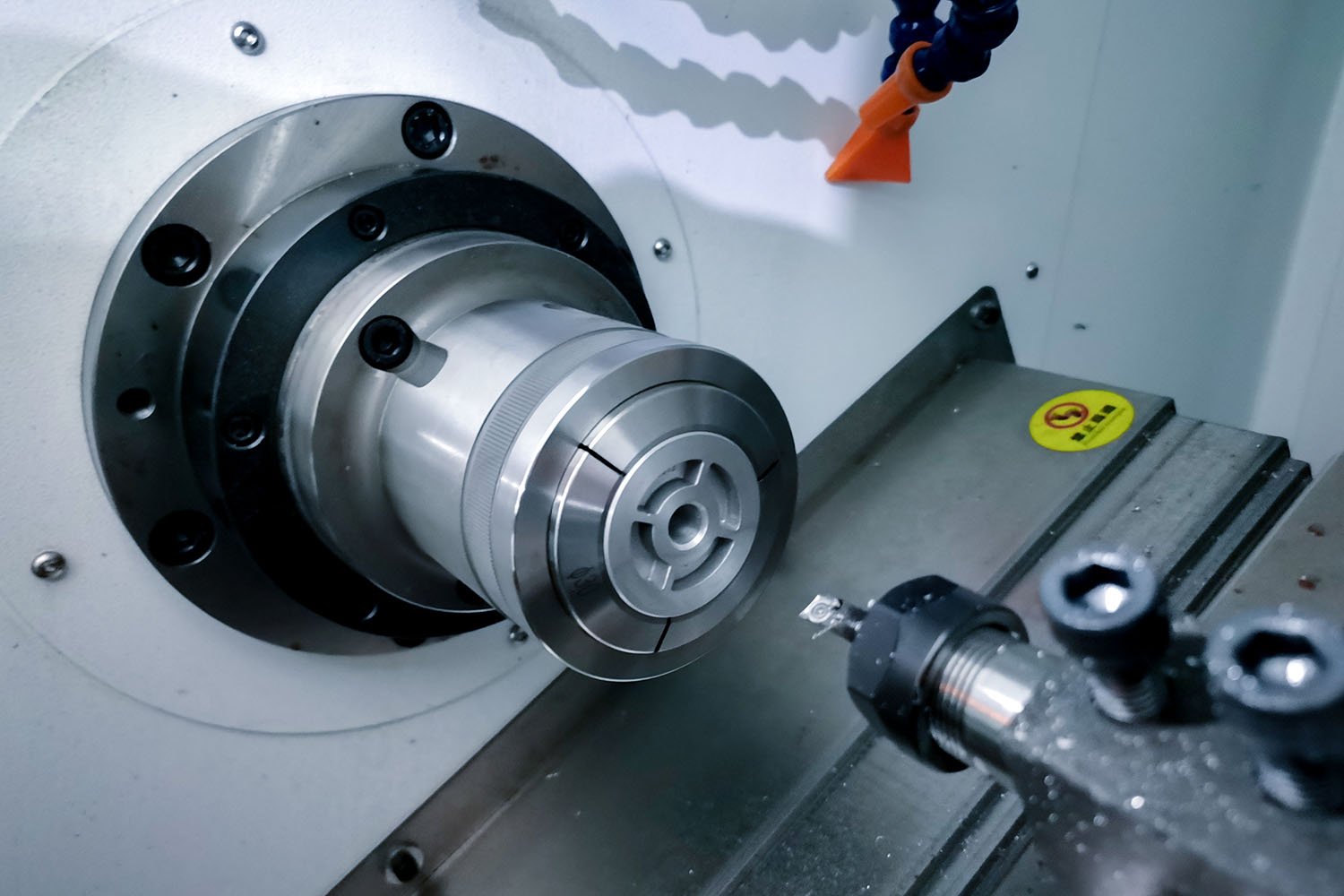

The Benefit of Collect Chuck VS 3- Jaw Chuck

Most CNC lathe users use three-jaw chucks as their standard work-holding equipment. It is one of the most commonly utilized chuck types in a variety of turning applications. That does not, however, imply that it is the ideal chuck for all jobs. A collet chuck is a work-holding device that also relies on mechanical forces to keep a workpiece in place. While a collet chuck cannot accept the same wide variety of workpiece sizes as a jaw chuck, it does provide advantages in speed, precision, and productivity that are important for some operations.

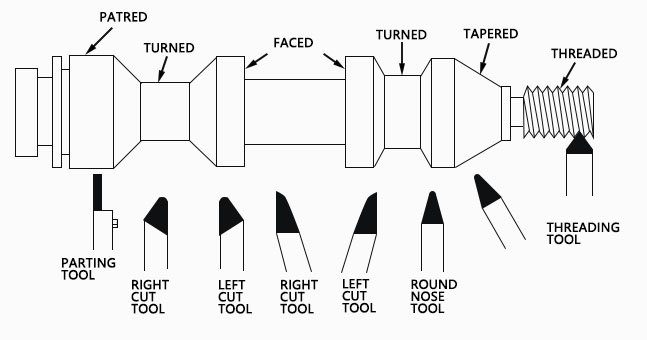

How to Select Lathe Tools Use in Smartlathe CNC Lathe

The CNC lathe machine is an advance manufacturing technology that enables machine shops to create turned parts precisely and accurately. To produce high-precision parts, this machine embeds the intelligent nature of computer numerical control (CNC) technology with various lathe tools.

Benefits & Advantages of Turning & Milling Machine

The Fourth Industrial Revolution is all about greater speed, higher efficiency, and consideration for sustainability. In such a landscape, automation will continue to play a key role in manufacturing activities while modernized, data-driven tools and equipment like CNC Lathes and CNC machining will drive innovation.

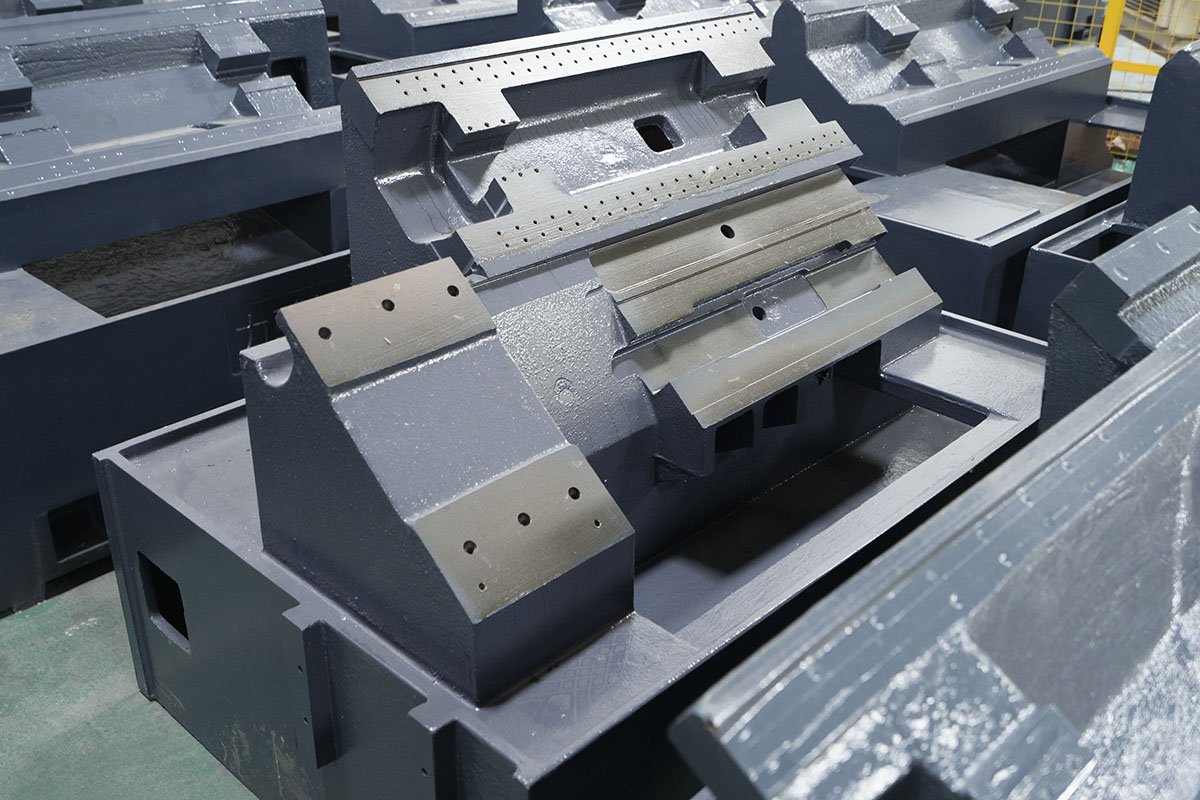

What Is the Difference Between Flat Bed And Slant Bed CNC Lathe?

Flat bed CNC lathe is mainly used for heavy-duty turning and is widely used for machine complex geometries, short shafts, discs, and other workpieces. Slant bed CNC lathe is usually equipped with a multi-station turret or live tooling, which is an automatic machine tool with increased precision, high speed, and high accuracy.

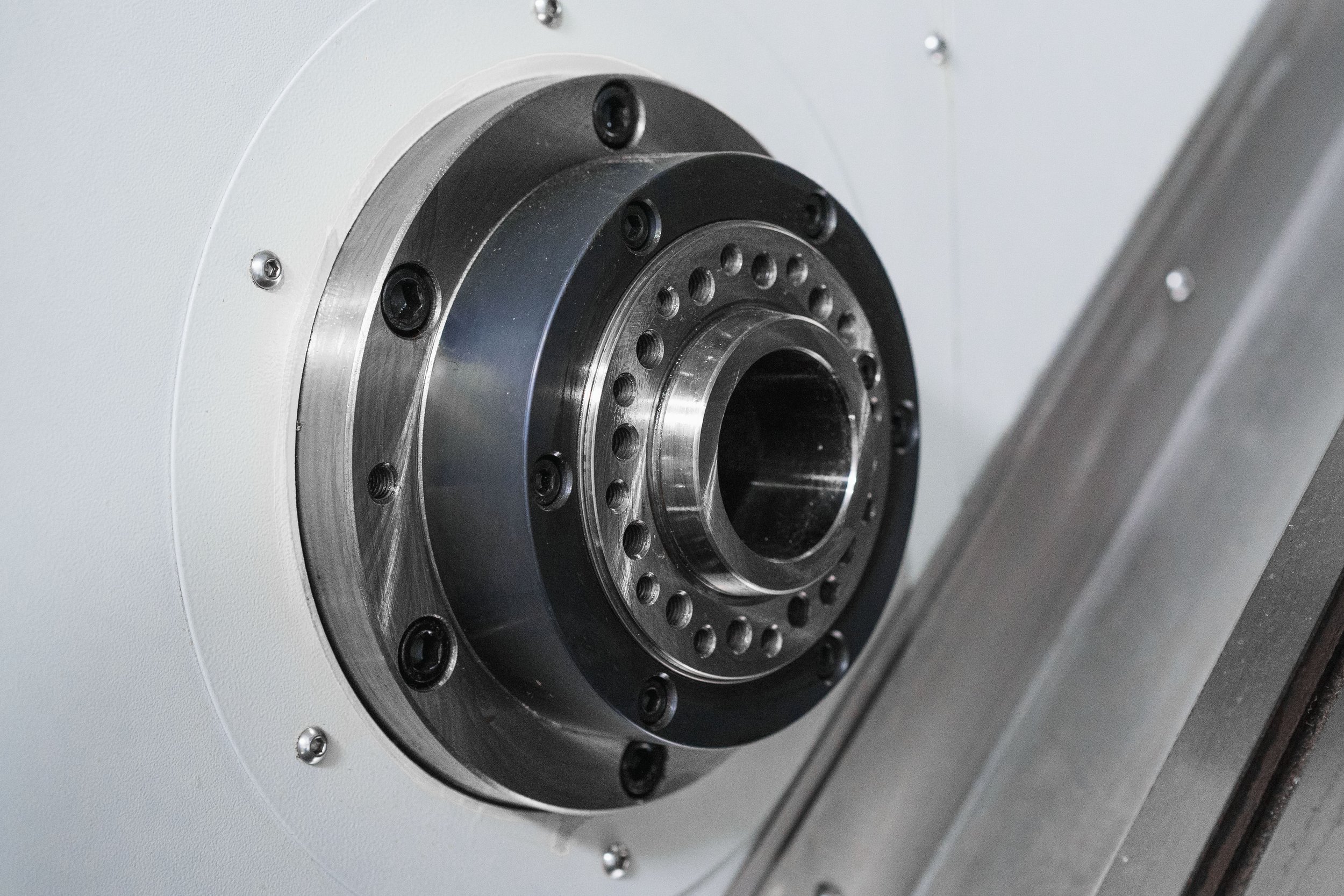

Overview of Electric Built-in Spindles Used in CNC Lathe Tools

The machine tool spindle is the axis of motion that drives the tool or workpiece on the machine tool to rotate to produce cutting motion. According to the different ways of the spindle drive, machine tool spindles can be divided into two categories: mechanical spindles and electric spindles.

What can CNC lathe Make

CNC machines are used in areas that require precision and accuracy as well as repetitiveness. Long ago, the precision required for tasks such as bolt manufacturing could only be accomplished by humans. These machines, on the other hand, have long outperformed human capabilities. They are machines that are more accurate than humans and can repeat the operation multiple times. CNC machines are capable of producing nearly identical parts over and over again.

What Is the Difference between CNC Milling and CNC Turning?

When customers need a metal product with a complex shape, they frequently ask for CNC machine. While it is popular to use this broad word to refer to any manufacturing method, CNC machining actually encompasses two distinct processes.

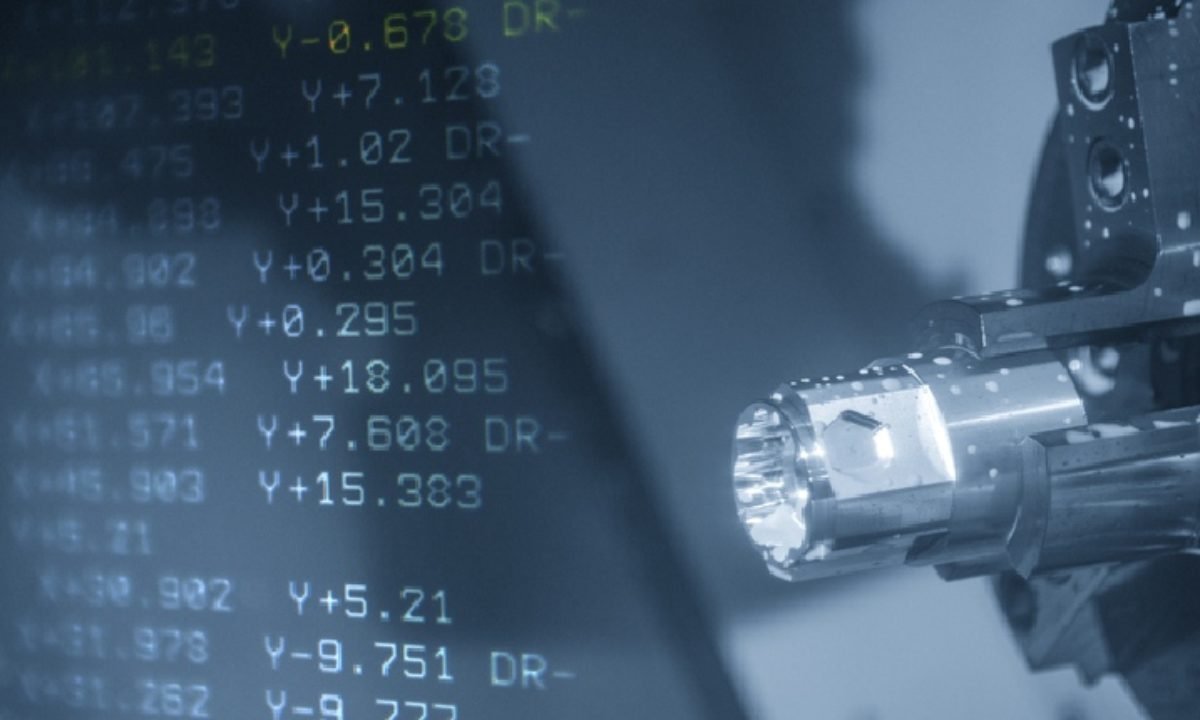

CNC machine programming origin and programming coordinate system

CNC machine tools have CNC device, machine operators, process programmers three different application objects, thus resulting in three coordinate systems: machine tool coordinate system (for the bottom of the CNC device coordinate system), the workpiece coordinate system (for the middle of the machine operator coordinate system), lathe programming coordinate system (for the upper level of the process programmer coordinate system). Correct selection and determination of the three coordinate systems, understanding the relationship between the three is very necessary for CNC machining and CNC programming.

How to improve the machining accuracy of CNC Gang Type Tool

CNC Gang Type Tools are used more and more in automated processing, and the precision is also getting higher and higher. Foshan Micro-control Industrial Automation Technology Co., Ltd. has self-developed CNC system, and combines this advantage to focus on the production of CNC knife arranging machines. So how to improve the machining accuracy of CNC cutter arranging machine? The cost of a CNC cutter arrangement depends on this.

How to choose a high precision CNC lathe?

The CNC lathe is now being used by more and more people because it saves labor and provides high precision, but the fish and dragon mix. The following small CNC lathe will introduce how to choose a high-precision CNC lathe.

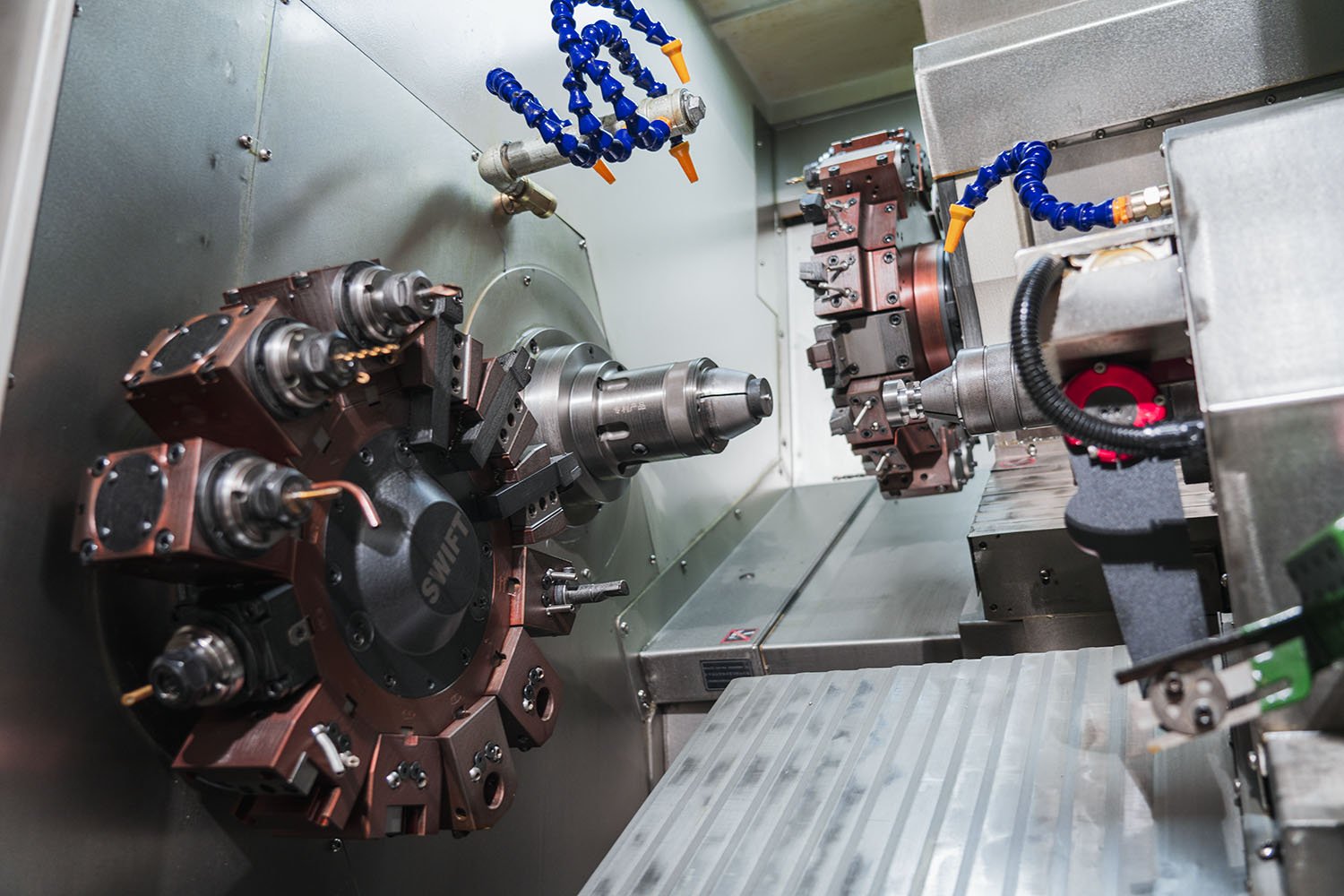

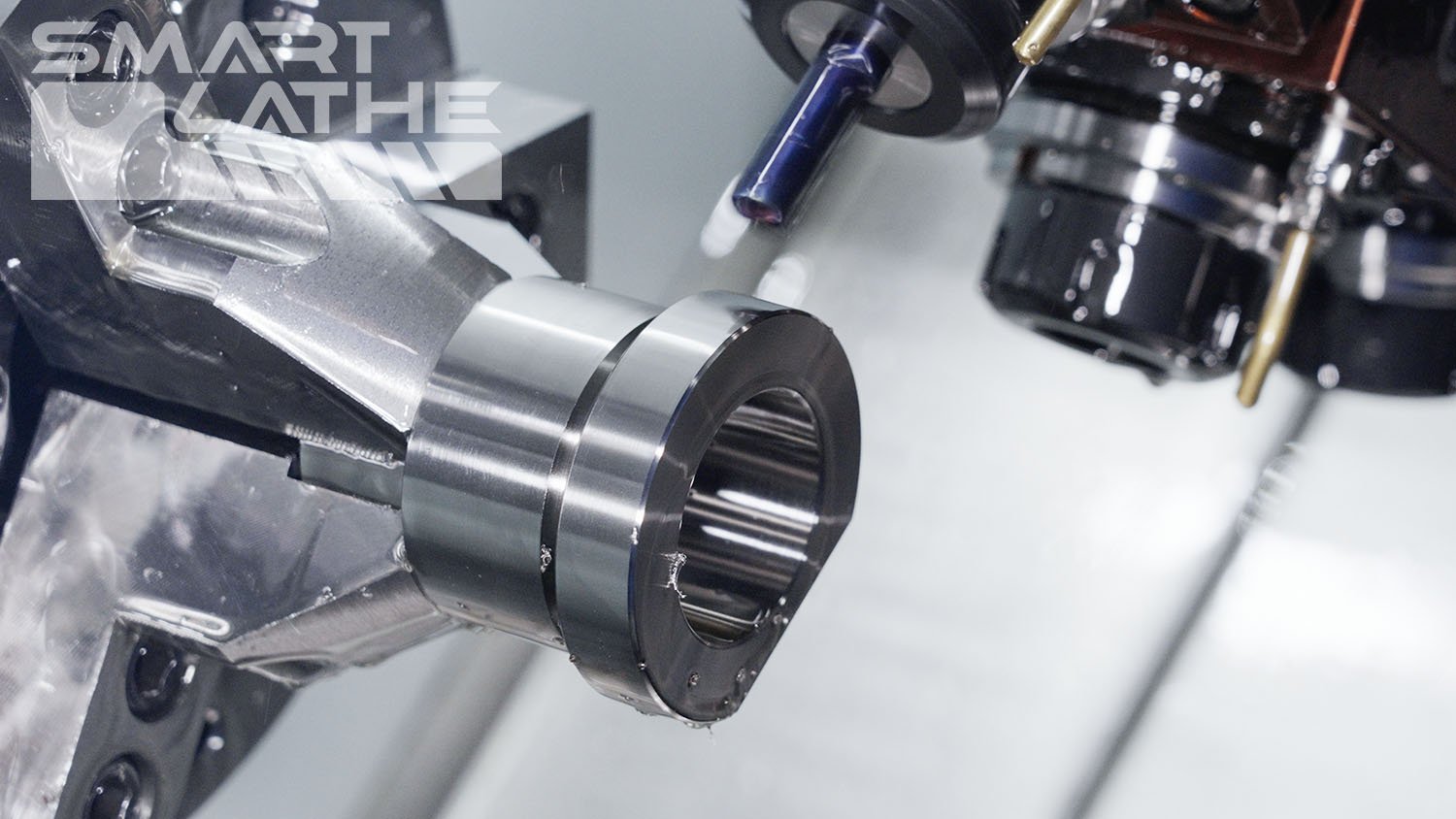

Knowledge about Dual Spindle CNC Lathe

We continue to invent and develop new technologies in the field of CNC lathes in order to offer greater quality and productivity. The definition of a dual-spindle CNC lathe will next be explained.

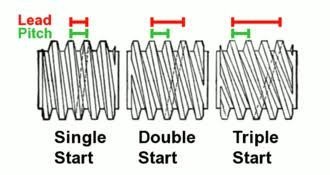

What distinguishes a single-start thread from a multi-start thread?

Lead screws are made of a cylindrical round thread that is spiraled into a screw shape by a single helix throughout its entire length. The threads may have, for instance, a metric thread form, a trapezoidal thread form, or the igus® dryspin® geometry. The dryspin® thread has a high helix thread-like structure.

The difference between servo turret and power turret of CNC lathe

Turret CNC lathe is a very important part of CNC lathe, at present, domestic CNC turret is mainly electric, divided into vertical and horizontal, with four stations, eight stations, ten stations and twelve stations, etc., which can rotate in forward and reverse directions and select knives nearby, and is used in various CNC lathes.

What Does a Lathe's Tailstock Do

On a lathe, machining activities entail rapidly rotating long, slender workpieces. By turning the tailstock of the lathe, you can prevent the workpiece from vibrating and bending unintentionally as a result of this. But what precisely is a tailstock and how does it benefit the lathe's machining? This paper provides a detailed guide to the tailstock of a lathe by discussing the components, functions and types of tailstock. In addition, this article discusses practical aspects of everyday machining, such as methods of aligning the tailstock to achieve high quality output.

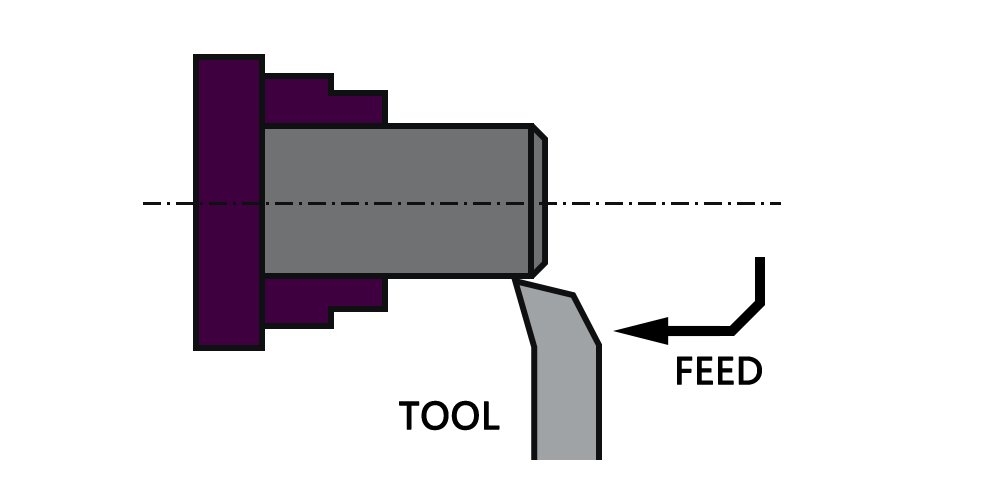

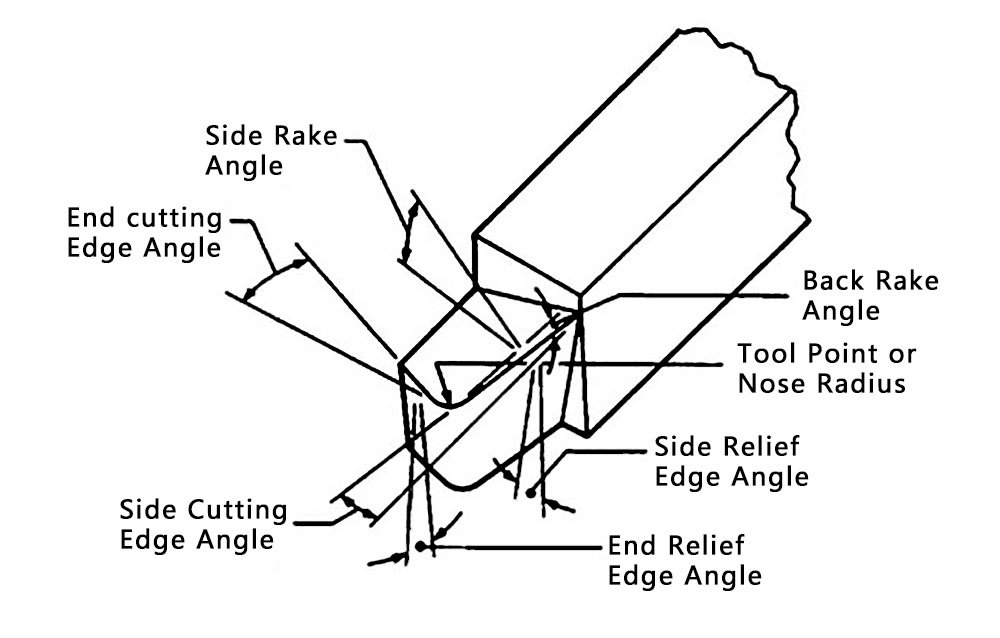

Components Of A Lathe Cutting Tool

Although lathe machine tools have different designs for their functions and applications, they all have specific parts in common. Below are the parts commons to every type of lathe cutting tool.

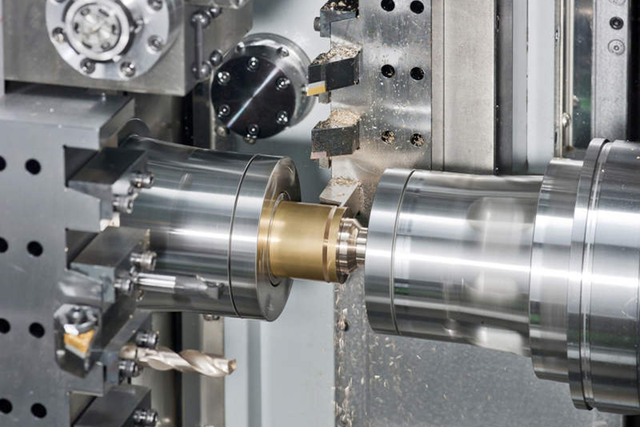

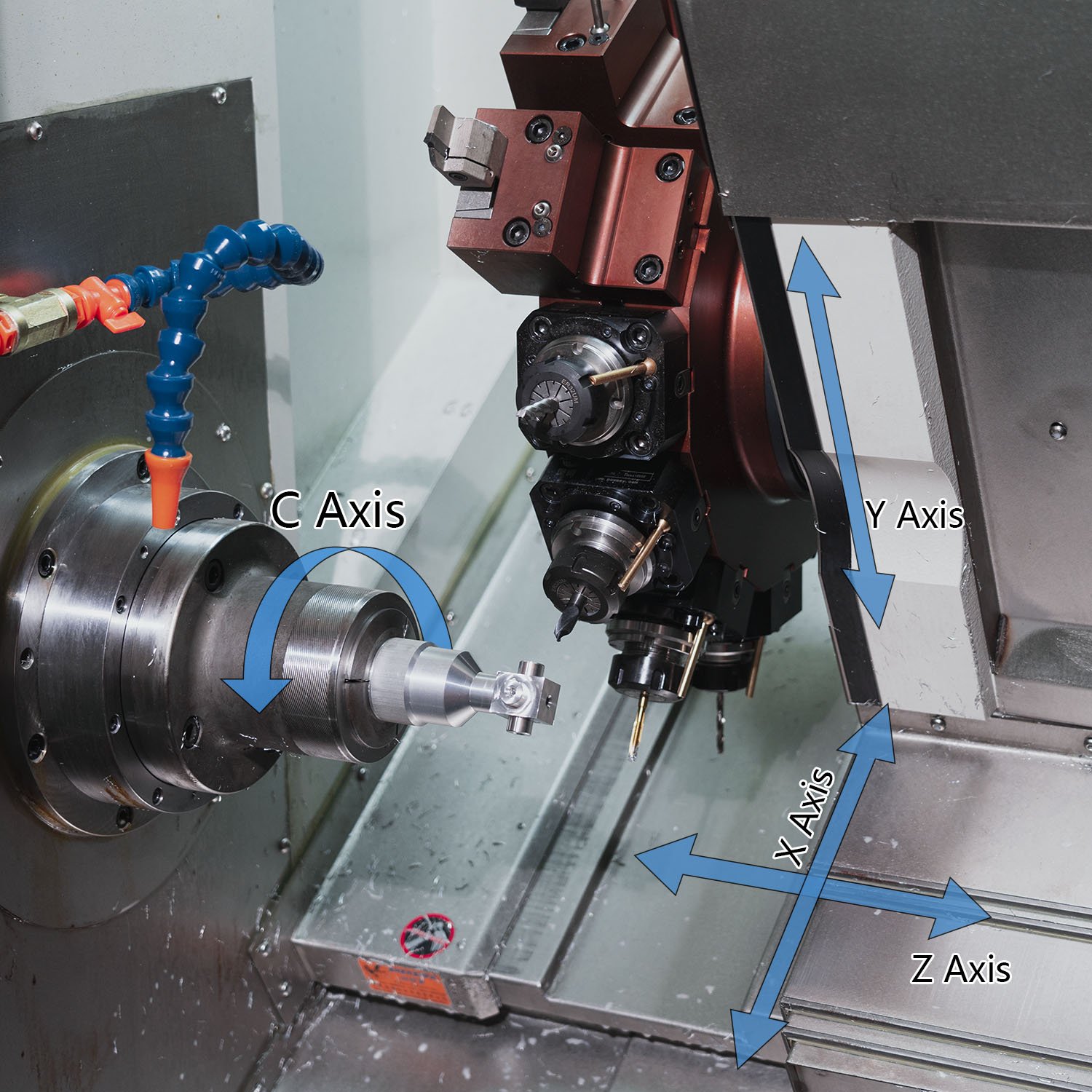

A SUMMARY OF MILL-TURN TECHNOLOGY

The different types of mill-turn machines range from the more basic 3-axis lathes (XZ&C), where the spindle is turned into a separate axis that can be rotated for milling operations, to the more sophisticated 6-axis machines, which also have a secondary programmable sub-spindle or counter-spindle and a linear Y-axis. The W-axis is used to position the secondary spindle for machining on machines that have one.

How much do you know about Swiss type CNC lathe?

CNC lathes are automated tools used to produce parts for the aerospace, automotive, and medical sectors. There are two common types of CNC lathes utilized in the industry: Swiss type and gang type. In this essay, we shall contrast and compare CNC lathes of the Swiss type and the gang type.

The Introduction of The Auxiliary for CNC Lathe Machine

The optional auxiliary for a CNC lathe can vary depending on the specific machine and its configuration. However, some common optional auxiliaries that can be added to a CNC lathe for enhanced functionality and capabilities.

A Comparative Analysis of Swiss-Type and Gang-Type CNC Lathes: Processing Examples

Swiss-type and gang-type CNC lathes are two distinct machine tools widely used in the manufacturing industry. While both offer unique advantages, they differ in terms of design, capabilities, and applications. This essay aims to provide a comprehensive comparative analysis between Swiss-type and gang-type CNC lathes, with a focus on processing examples to highlight their differences and advantages in various machining applications.

C axis functionality in CNC lathe

The C-axis functionality in CNC lathes refers to the ability of the lathe to rotate the workpiece or the spindle in synchronization with the X and Z-axis movements. This rotational axis adds a new dimension of versatility and precision to the machining process. Here are some key aspects and benefits of the C-axis functionality:

Choosing gang tooling or a turret for a CNC lathe

The easiest way to decide between gang tooling and turret lathes is to carefully consider the kinds of parts that will be created and the advantages those particular parts will gain.

You will probably prefer a Turret if you are unsure of the kind of parts you will eventually produce and are unwilling to accept the restrictions of gang tooling to smaller diameter shorter items. The turret lathe is probably what you want if you want the smallest learning curve and the easiest programming imaginable. On the other hand, gang tooling is a good option if you want the quickest cycle times so you can produce as many of the parts created on gang lathes as possible at a low cost.