SWISS TYPE CNC LATHE

SW-Series

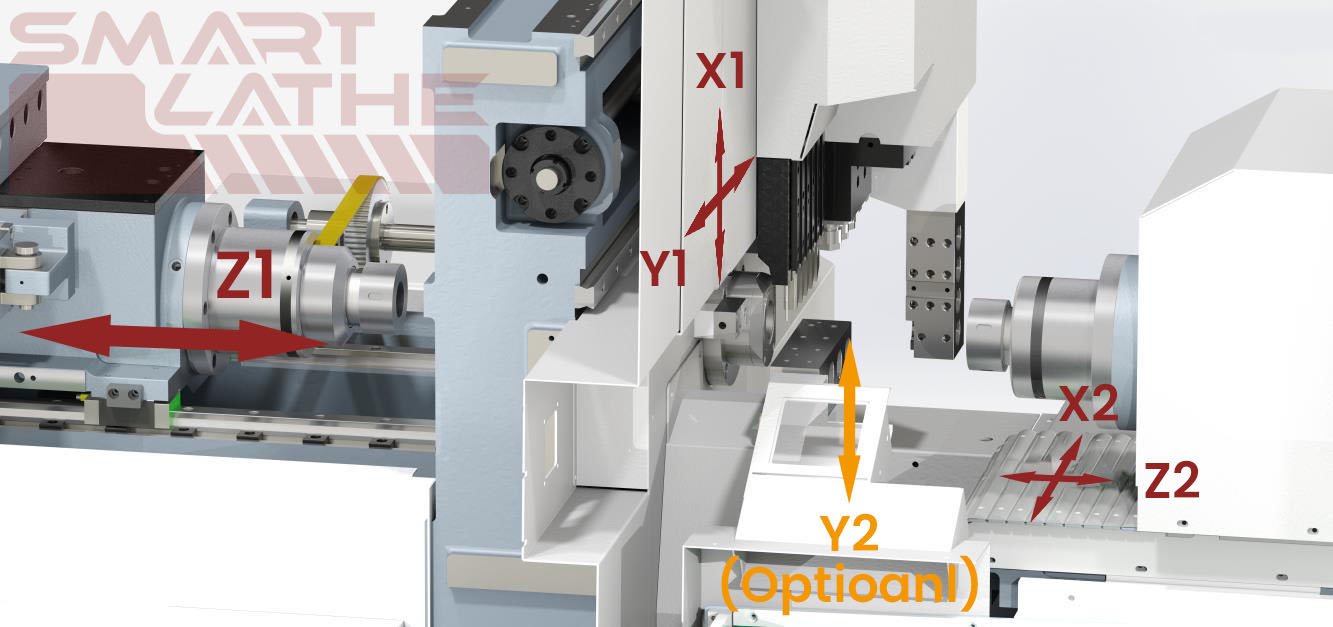

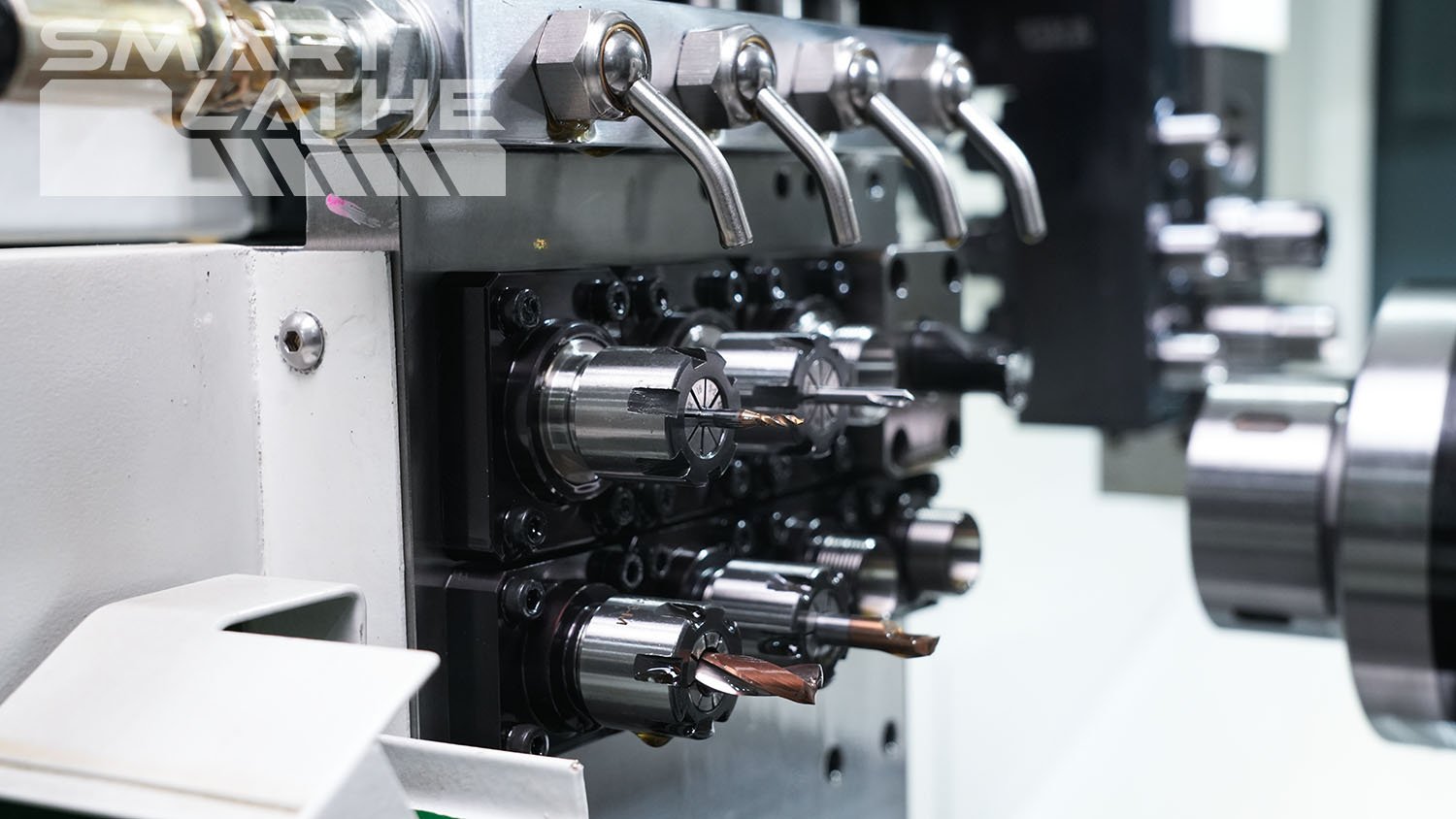

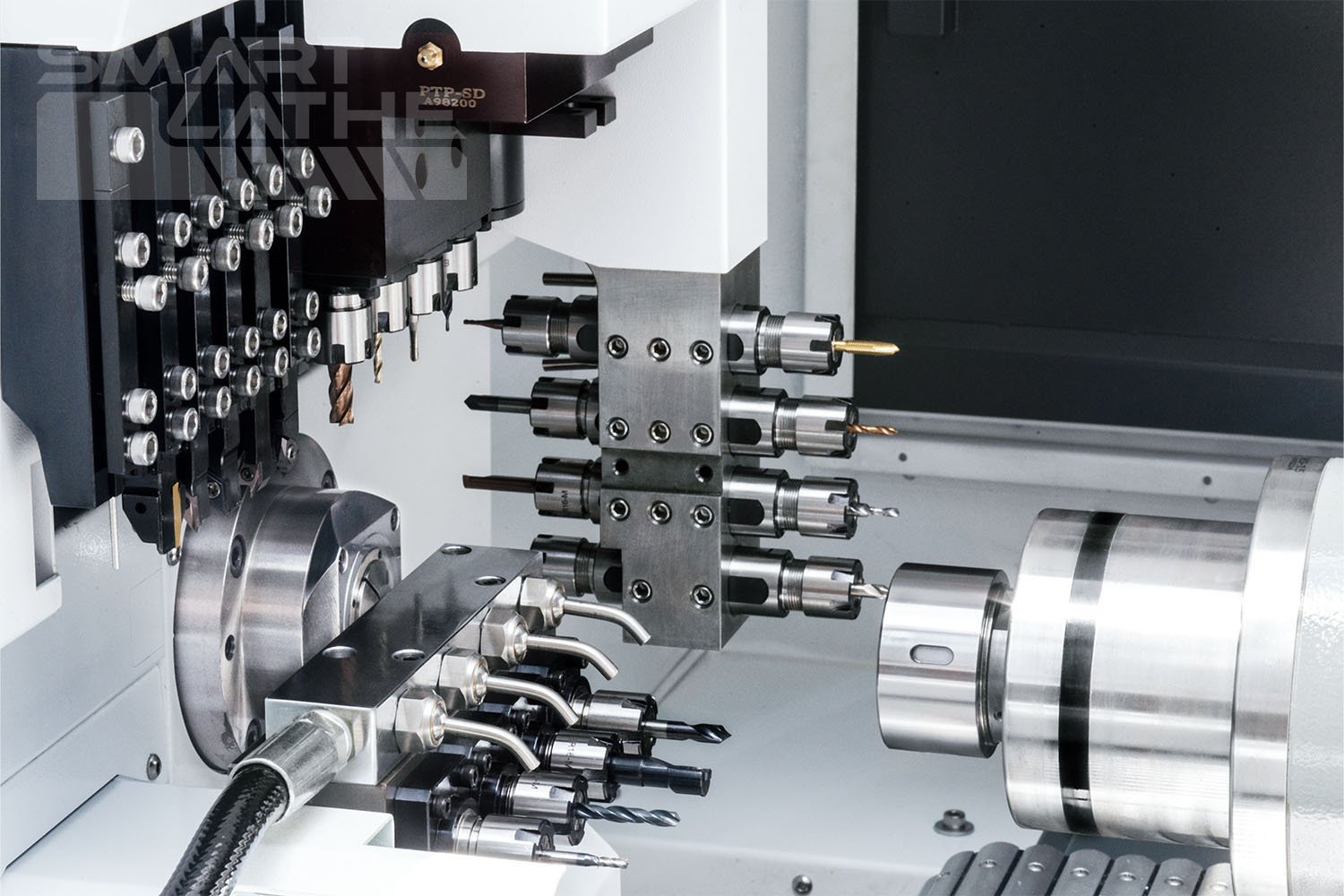

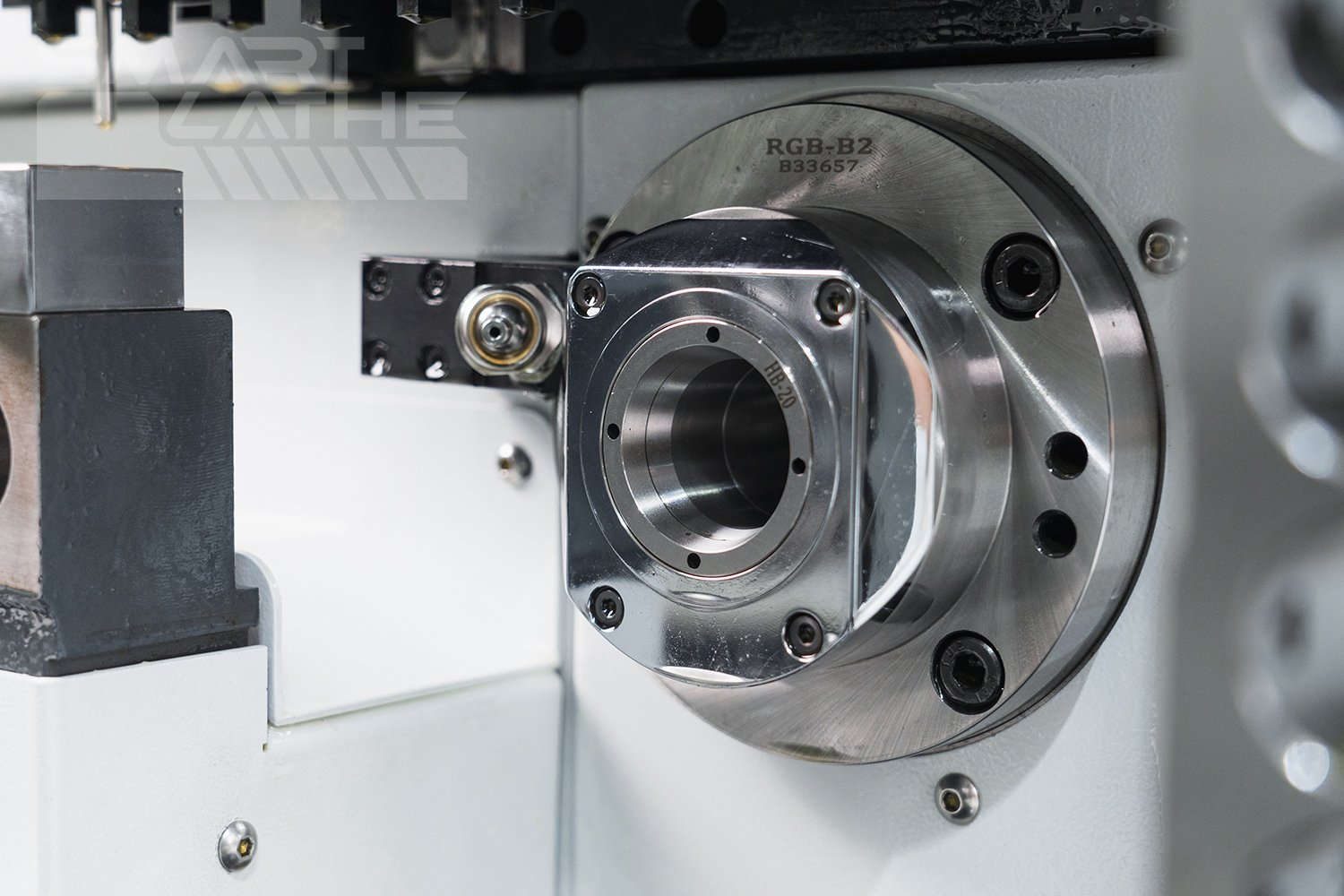

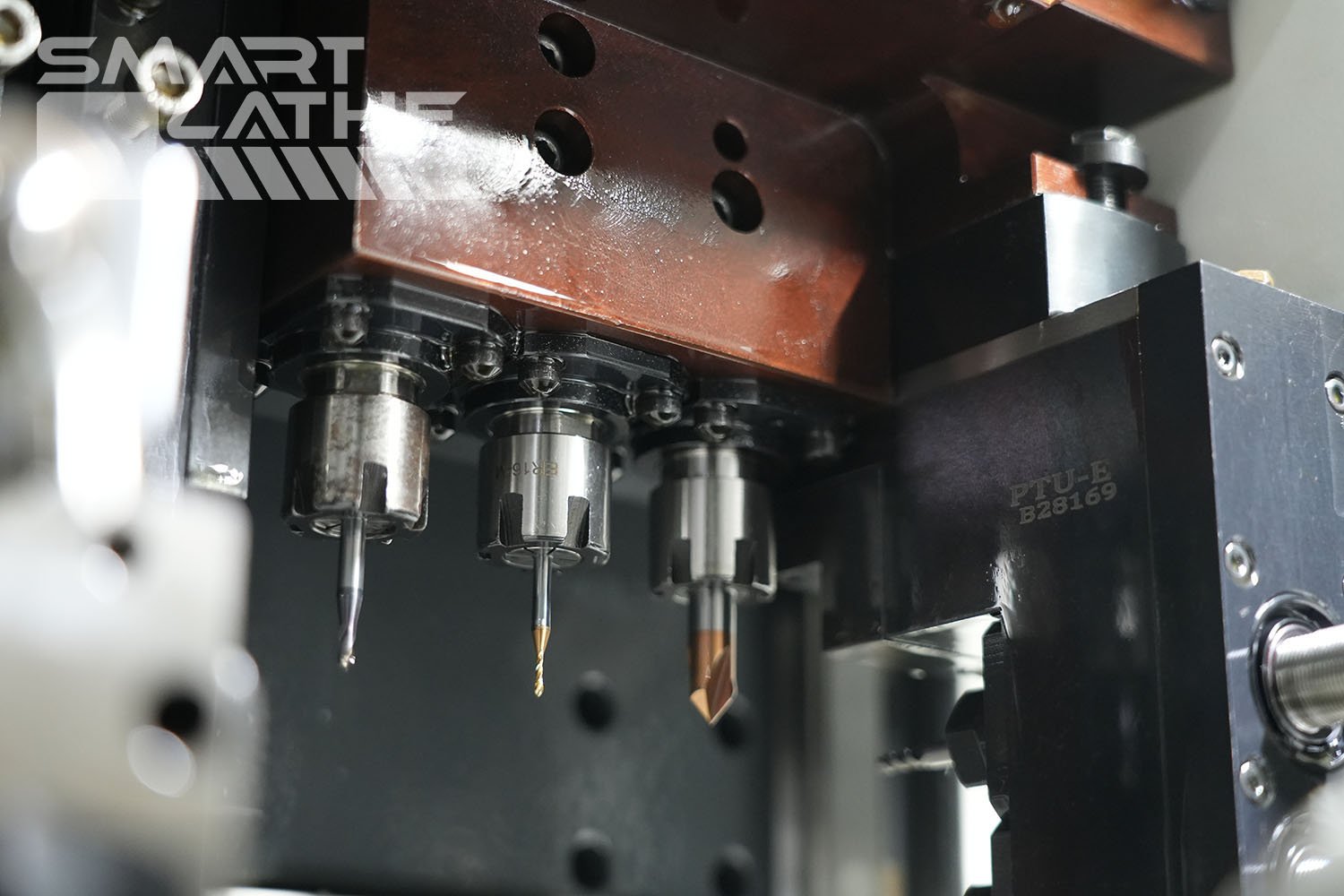

The SW-series Swiss-type lathe uses a sliding headstock and a guide bushing to support the workpiece, allowing for precise and accurate machining of small and intricate parts. The machine is known for its ability to perform multiple operations on a single workpiece, including turning, drilling, milling, and tapping, in a single setup, which reduces the need for additional machines and handling.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | |||||||

|

|||||||

| Optional | ||||||||

|

||||||||

Application

This type of lathe is particularly useful for producing long and slender parts, such as medical instruments, watch components, and aerospace parts, where high precision and accuracy are required. The machine's advanced technology and flexibility make it ideal for mass production, prototyping, and customized production.

Swiss lathes be used extensively to produce parts for the electronics and semiconductor industries, medical technology, aerospace, and high-end industrial markets applications. Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars material.

Case Study

Configuration: SW-266 installs the sandard configuration

Workpiece: 185mm long bolt, Brass.

Machining Process: Turning, Facing, Drilling, Thread turning.

Turning Duration: within 125 seconds of one-time processing