Characteristics of Thread Milling on VMC

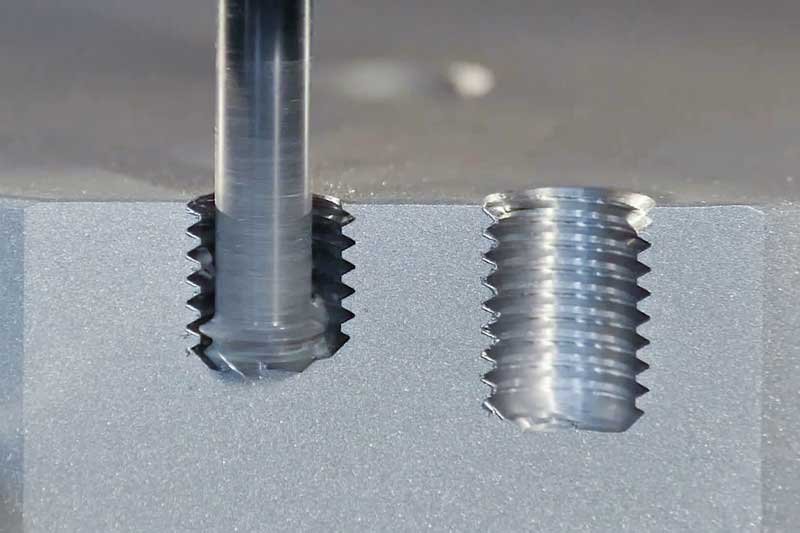

Thread milling on a vertical machining center (VMC) is a high-efficiency process that uses a milling cutter to machine threads. Compared to traditional thread machining methods, such as tapping and turning, thread milling on a VMC offers several advantages:

1. High Precision

Thread milling on a VMC achieves high-precision threading through precise CNC programming and tool control. It is particularly effective for machining large-pitch or multi-lead threads, ensuring accuracy in diameter, pitch, and thread shape. This makes it suitable for applications requiring high-precision threads, such as in aerospace and precision machinery fields.

2. Ability to Machine Various Thread Types

VMC thread milling can produce different thread types, including internal and external threads, inch threads, metric threads, and tapered threads. Its flexibility allows for various thread types to be machined on the same equipment by simply adjusting tools and programming parameters, reducing both equipment investment and tool change time.

3. Applicable to Various Materials

Thread milling on a VMC is suitable for machining various materials, including aluminum, steel, stainless steel, titanium alloys, and hard alloys. The cutting force in the milling process is low and evenly distributed, making it effective even on high-hardness or difficult-to-machine materials.

4. Reduced Risk of Tap Breakage

Compared to traditional tapping, the milling cutter used in VMC thread milling is less prone to breakage, especially in hard materials or deep-hole machining, thereby reducing processing losses and repair time.

5. Reduced Cutting Force Prevents Workpiece Deformation

The cutting force in VMC thread milling is small and evenly distributed, making it suitable for thin-walled workpieces and large-diameter threads, with minimal risk of workpiece deformation or thread surface damage.

6. Long Tool Life

Every cutting edge of the thread milling tool on a VMC participates in the cutting, resulting in a smooth process and uniform wear on the tool.

Compared to traditional tapping, thread milling tools have a longer lifespan, reducing tool change frequency and processing costs.

7. Reduced Spindle Wear

Unlike thread tapping, VMC thread milling does not require abrupt stopping and reversal of the spindle at the bottom of the thread. This significantly extends the spindle's life and reduces spindle wear, contributing to energy savings.

8. High-Quality Surface Finish

The larger cutting edge contact area and stable cutting in VMC thread milling produce less chip, resulting in a high-quality thread surface finish. This reduces the need for post-processing, making it ideal for applications requiring high surface quality.

Thread milling on a VMC is an efficient threading method that offers high precision, flexibility, long tool life, and compatibility with various materials and workpiece shapes.

It avoids common issues in traditional tapping, such as tap breakage and high cutting force, making it increasingly popular in modern manufacturing, especially in precision and complex material processing fields.