CNC lathes are capable of turning not only circles but also polygons.

Usually, the surface machining of the rotating body is performed on a lathe.

However, often due to lack of equipment or unbalanced machine tool loads, other (non-turning) processing, such as polygonal processing, grinding, rolling, and thread milling, can also be performed after technical transformation of the lathe.

Facts have proved that taking technical measures according to local conditions not only has small investment, quick launch and good effect, it is a good way to make up for insufficient or unmatched equipment, and it is also an important way to expand the use of lathes, especially for small and medium-sized factories. Enterprises have more practical significance.

How Machining Polygons Works

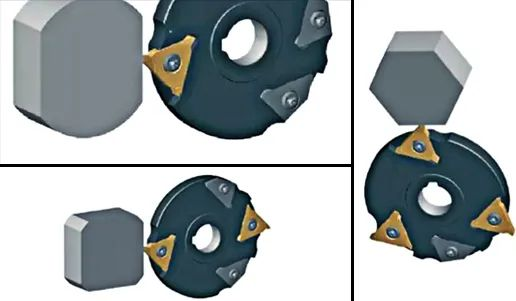

To process a polygonal workpiece on a lathe, it is necessary to install a set of special devices as shown in the figure.

When turning, it is installed on the middle sliding plate, so that the workpiece and the tool rotate in the same direction, and the relative movement between the tool and the workpiece is realized by using the speed ratio relationship between the tool and the workpiece with a certain number of cutter heads, so that it can be realized according to the law of generation. Surface forming, complete the processing of square, hexagonal, regular triangle, trapezoidal, drum-shaped, waist-shaped, flat, rhombus, irregular polygon and polygonal workpieces with taper.

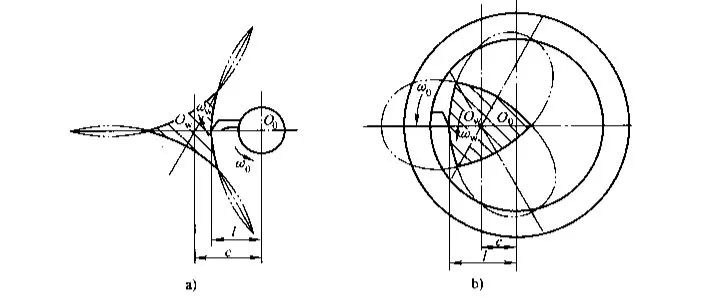

For example, if a regular triangle is processed, the transmission ratio between the tool and the workpiece is i=3, so the trajectory of the tool tip relative to the axis of the workpiece during the cutting process is a periodically repeated closed curve, and the middle part surrounded by the curve forms an approximate triangle.

If the workpiece axis is outside the tool tip motion circle, it is called "external cutting method" and the triangle presented is shown in Figure a; if the workpiece axis is located within the tool tip motion circle, it is called "internal cutting method", and the triangle presented is as follows As shown in Figure b.

It can be seen from the presented triangular figure that no matter whether the external cutting method or the internal cutting method is used, each surface of the processed triangular workpiece is not a plane, but a circular arc surface that is close to the plane. Therefore, the method of turning polygons mentioned above is only It can be used in processing that does not require high surface flatness.

Now widely used tool introduction

The above introduction is a traditional theory, but in practical applications there are different forms of cutting tools, the principle is the same, but in the introduction of the principle, the main movement of the cutting tool is on the spindle, and the auxiliary movement of the workpiece is done. In practical applications, the workpiece is mainly moved on the spindle.

In polygon turning, a flying cutterhead is used to cut out polygons (three to eight sides) on the side of an axisymmetric workpiece. The workpiece (main spindle) and the rotating tool (flying cutter head) work together in a synchronous coupling to machine the force surface.

The number of cut surfaces depends on the gear ratio and the number of cutting edges on the cutting tool. The workpiece rotates in the opposite direction to the tool.

Tool with two insets are used to cut quadrilaterals, and with three insets are used to cut hexagons, etc. If a different gear ratio is used or if the number of cutting edges of the tool is changed, large depressions or prominent deflection arcs may appear on the workpiece surface.

Because of this principle, the contour trajectory generated by the tool tip point is exactly an ellipse, but the curve implemented on the wrench force surface is a section with a larger curvature radius in the ellipse, so it does not affect the assembly of tightening and loosening operate.