How to judge processing by cutting

In metal cutting, some chips are rolled into coils and break off when they reach a certain length; some chips are broken into C-shaped and 6-shaped; splashing around, affecting safety; some strip-shaped chips are wrapped around the tool and workpiece, which is easy to cause accidents. Poor chip removal status will affect the normal production. The use of chuck soft jaw.

Factors Affecting Chips

Work material

The alloy elements, hardness, and heat treatment state of the workpiece material affect the chip thickness and chip curl. Mild steel is thicker than hard steel to form chips; hard steel is less likely to curl than soft steel; the thickness of chips that are not easy to curl is thin; but when the thickness of soft steel chips is too large, it is not easy to curl. At the same time, the shape of the workpiece is also an important influencing factor.

Geometric parameters of tool cutting area

Reasonable geometric parameters of tool cutting area are the most common methods to improve the controllability of chip formation and the reliability of chip breaking.

The rake angle is inversely proportional to the chip thickness, and has the best value for different processed materials; the leading angle directly affects the chip thickness and width, and the large leading angle is easy to break chips; the radius of the tool nose arc is related to the chip thickness and width and chip flow direction, a small arc radius is suitable for finishing machining, and a large arc radius is suitable for rough machining.

The width of the chip breaker is selected in proportion to the feed rate. If the feed rate is small, choose the narrow one, and if the feed rate is large, choose the wide one; The feed rate is shallow.

Cutting amount

The three elements of cutting amount will limit the range of chip breaking. The feed rate and the amount of back engagement have a greater impact on chip breaking, while the cutting speed has the least impact on chip breaking within the conventional cutting speed. The feed rate is proportional to the chip thickness; the amount of back cutting is proportional to the chip width; the chip speed is inversely proportional to the chip thickness, increasing the cutting speed and narrowing the effective chip breaking range.

Machine tools

Modern CNC machine tools use the NC editing function to periodically change the feed rate to achieve the purpose of forced chip breaking, which is usually called "programmed chip breaking". This method has high chip breaking reliability, but low cutting economy. It is often used in processes where chip breaking is difficult by other methods, for example, circular deep grooves on the end face of a car, etc.

Cooling and lubrication state

With the addition of cutting fluid, the effective range of chip breaking becomes wider, especially in the case of chip breaking with small feed and easy curling. Using the high pressure of cutting fluid to break and remove chips is an effective way in some processing methods. For example, in deep hole processing, high-pressure cutting fluid can discharge chips out of the cutting area.

Chip Shape Formation Process

The formation process of banded chips can be divided into three stages:

Basic deformation stage: the deformation of chips during the process when the cutting layer metal and the cutting edge of the tool come into contact with chips and separate from the workpiece material;

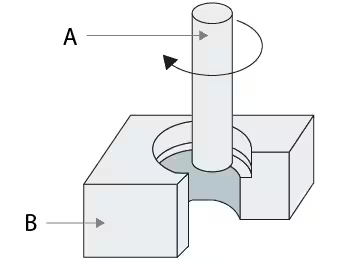

Curl deformation stage: upward curl, side curl, tapered curl with both A and B directions;

Additional deformation and breakage stages.

Classification of chips

Due to different workpiece materials, cutting conditions vary. Chip shapes generated during cutting are various. Chip shapes are mainly divided into four types: ribbon, nodular, granular and broken.

1. Ribbon chips

This is the most common type of chipping. Its inner surface is smooth and its outer surface is hairy. When processing plastic metal, such chips are often formed under the working conditions of small cutting thickness, high cutting speed and large tool rake angle. It has a balanced cutting process, less fluctuation of cutting force, and less roughness of the machined surface.

2. Nodular chips

Also known as crushed chips. It has a jagged outer surface and sometimes cracks on the inner surface. Such chips are often produced when the cutting speed is low, the cutting thickness is large, and the rake angle of the tool is small.

3. Granular chips

Also known as unit chips. In the process of chip formation, if the shear stress on the shear plane exceeds the fracture strength of the material, the crack spreads to the entire surface, and the chip unit falls off from the cut material to form granular chips

4. Breaking chips

These are chips belonging to brittle materials. The shape of this chip is irregular, and the machined surface is uneven. From the perspective of the cutting process, the chips deform very little before breaking, and the chip formation mechanism of plastic materials is also different. Its brittle fracture is mainly due to the stress on the material exceeding its tensile limit. Processing brittle and hard materials, such as high-silicon cast iron, white iron, etc., especially when the cutting thickness is large, such chips are often obtained. Because its cutting process is very unstable, it is easy to damage the tool and damage the machine tool, and the machined surface is rough, so it should be avoided in production. The method is to reduce the cutting thickness to make the chips into needles or flakes; at the same time, appropriately increase the cutting speed to increase the plasticity of the workpiece material.

The above are four typical chips, but the chips obtained at the processing site have various shapes. In modern machining, the cutting speed and metal removal rate have reached a very high level, and the cutting conditions are very harsh, often producing a large number of "unacceptable" chips.

Appropriate measures are taken during cutting to control the curling, outflow and breaking of chips, so that an "acceptable" good chip shape is formed. The most widely used chip control method in actual machining is to grind a chip breaker on the rake face or use a briquetting chip breaker.