Smartlathe Brain System Chuck Clamping Mode Switch: Internal and External Clamping

In the daily CNC lathe production process, it is often necessary to change the chuck clamping method depending on the workpiece clamping needs. The smartlathe brain CNC lathe control system sets the parameters for switching between internal and external clamping. It is possible to quickly switch between the clamping methods by changing only one parameter setting.

1. Chuck Clamping Directions

Internal Clamping: In this method, the chuck jaws expand outward from the inside of the workpiece to hold it at the center of the chuck. This is suitable for workpieces with enough internal space for the jaws to grip.

External Clamping: Here, the chuck jaws move inward from the outside of the workpiece, securing it at the chuck center. This is the most common clamping method.

2. Purpose of Internal and External Clamping

Internal Clamping is suitable for workpieces that need to be machined based on the inner hole or when the workpiece cannot be held externally and requires clamping by the inner diameter. For example, when turning workpieces with a large internal diameter, internal clamping can fix the workpiece, allowing the machining tool to align accurately with the workpiece's central axis, improving machining precision and surface quality.

External Clamping is widely used for processing various shaft parts and disc-shaped parts. For larger workpieces, external clamping is also the primary method, as it provides sufficient clamping force to ensure the stability of the workpiece during machining.

3. Precautions for Internal and External Clamping

When using internal clamping, check the workpiece’s inner diameter to adjust the clamp size, ensuring even clamping force. Avoid excessive clamping force to prevent deformation or damage to the workpiece. Adjust the clamping force according to the material, size, and machining requirements of the workpiece to prevent loosening or damage during processing.

When using external clamping, ensure the clamping force is evenly distributed. Choose an appropriate jaw shape and clamping method based on the workpiece size. For larger workpieces, consider the chuck’s load capacity and clamping force to avoid overload or loosening.

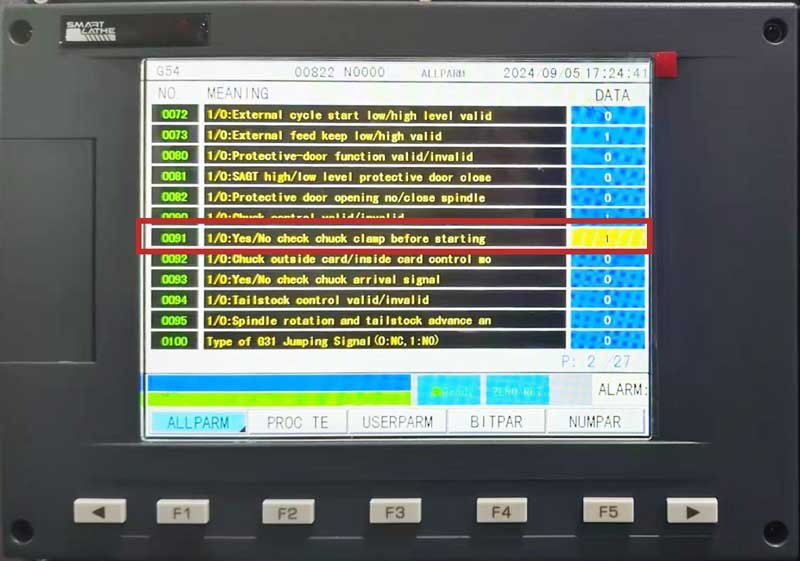

4. How to Switch the Chuck Clamping Direction in the System

Power on the machine, and on the control panel, locate the parameters and click to enter.

Go to the parameter page, find parameter number 0092 in the machine’s parameter list. To switch to internal clamping, input "1" and press "Enter". After entering the machine password, the internal clamping function will be activated. To enable external clamping, input "0" instead, and the external clamping function will be activated.