Spin Window on CNC Lathes

The observation window is an important auxiliary tool on CNC lathes.

1. Main applications of observation window on CNC lathes:

Process monitoring: The observation window allows operators to observe the machining process of workpieces on CNC lathes in real time.

Tool wear detection: Through the observation window, operators can observe the wear condition of tools.

Safety monitoring: The observation window is used to monitor the safety around the lathe, including workpiece clamping devices, tool movement trajectories, and the operating status of the machine itself.

Fault diagnosis: The observation window can help operators observe whether there are any abnormal phenomena during the operation of CNC lathes, such as vibration, unusual noises, etc.

2. Spin Window on CNC Lathes

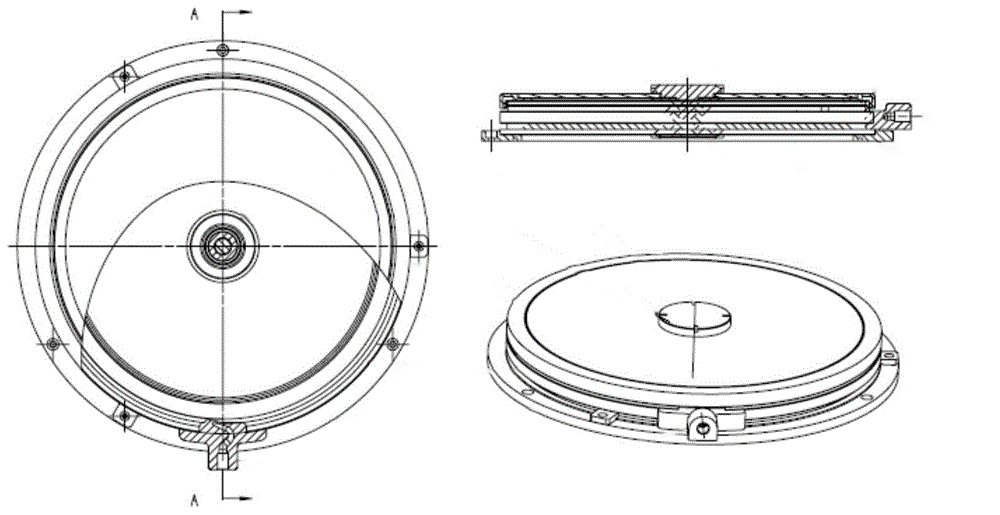

The Spin Window is a method for observing the machining process of workpieces. Unlike traditional windows, the Spin Window is a structure consisting of a transparent cover plate and a rotating axis installed on the lathe. It is driven by a motor to rotate, presenting a rotating state on its surface. This structure enables operators to monitor the machining process in real time, improving machining quality and efficiency.

3. Advantages of Spin Window over Traditional Viewing Windows

Higher clarity: Due to the centrifugal force generated by the motor driving the window to rotate, the coolant attached to the window detaches, forming a clear observation window.

Improved operational efficiency: Operators can monitor the machining process in real time, adjust tool positions and machining parameters promptly, thus enhancing machining efficiency and quality.

The introduction of the Spin Window has improved the efficiency and safety of CNC lathes, as well as enhanced the operational efficiency and skill level of operators.

Following a series of technical evaluations, SMARTLATHE has proposed an electrically operated visual observation window solution.