The Tool Changing System, Coolant Delivery System, and Chip Removal System of Vertical Machining Centers (VMC)

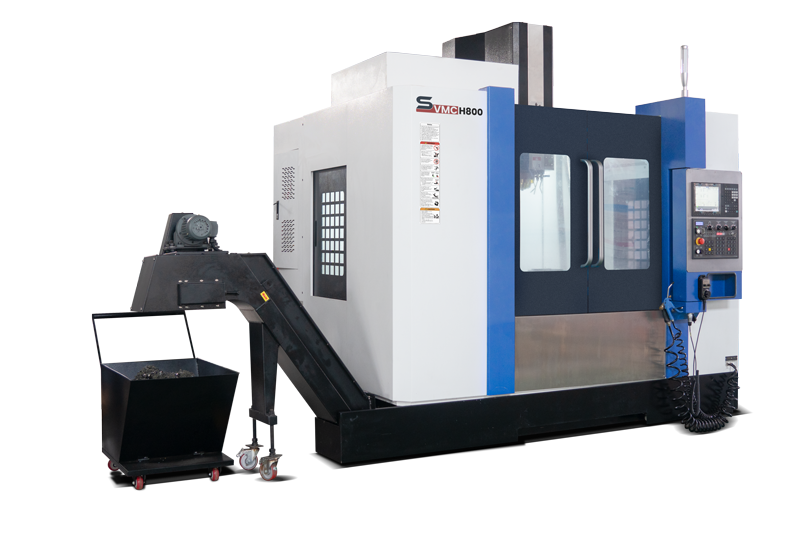

To achieve optimal machining performance, a Vertical Machining Center (VMC) is typically equipped with a high-quality tool changing system, coolant delivery system, and chip removal system. Additionally, factors like spindle speed, axis travel, and workpiece capacity are critical when considering a VMC.

1. Tool Changing System, Coolant Delivery System, and Chip Removal System

In VMC, the tool changing system plays a key role in automated operations, allowing cutting tools to be changed automatically during machining. A highly efficient coolant delivery system provides the necessary lubrication and cooling during high-speed cutting. As for the chip removal system, the ability to efficiently remove chips and manage waste is essential for maintaining a clean and safe working environment.

2. Tool Changing System

The automatic tool changer (ATC) on a Smartlathe Vertical Machining Center (SVMC) is highly efficient and crucial for seamless production processes, enabling quick and precise tool changes, reducing setup times, and enhancing overall productivity.

Tool Storage Capacity

One critical aspect of the tool changing system is its tool storage capacity. The SVMC offers ample tool storage, providing flexibility for a wide range of machining applications without frequent manual intervention to change tools. This functionality helps maintain a continuous workflow and improves output quality.

Tool Change Time

Different tool changing systems have varying tool change times. To further enhance productivity and minimize downtime, SVMC simplifies the tool change process, allowing operators to focus on machining tasks without delays caused by tool changes. This optimization contributes to a more efficient workflow and ultimately improves output quality.

The tool changing system in a VMC is vital for cost-effectiveness in overall production. By increasing tool magazine capacity, optimizing the tool changing method, and reducing tool change time, the SVMC brings cost benefits.

3. Coolant Delivery System

In the SVMC, the coolant delivery system plays a crucial role in ensuring efficient and precise machining operations. It helps reduce heat buildup during cutting, extends tool life, and improves surface finish, resulting in optimal cutting performance and enhanced overall productivity.

Reducing Heat Buildup During Cutting

The VMC delivers coolant at high pressure directly to the cutting area, effectively removing heat generated during the cutting process. This not only shortens cycle times but also improves production output.

Extending Tool Life

The coolant system enhances chip control and reduces tool wear, extending the lifespan of tools. By efficiently dissipating heat from the cutting zone, coolant prevents premature tool failure and ensures consistent long-term performance. This not only lowers maintenance costs but also minimizes downtime caused by tool replacements, further improving the efficiency of the entire machining process.

Coolant Filtration System

The coolant filtration system is essential to maintaining the quality and efficiency of the VMC's coolant delivery system. It removes contaminants from the coolant, ensuring it remains clean and free from impurities that could affect cutting performance.

In addition to removing contaminants, the coolant filtration system also regulates the temperature of the coolant, preventing overheating and ensuring consistent cutting performance. By maintaining the coolant at an optimal temperature, the SVMC reduces thermal expansion of machine components, thereby improving the accuracy of VMC operations.

4. Chip Removal System

Effective chip removal is critical in a VMC. The SVMC’s efficient chip removal system effectively expels chips from the work area, preventing chips from interfering with machining operations. This ensures uninterrupted production and reduces downtime caused by chip removal.

When selecting a VMC, in addition to considering essential factors such as spindle speed, axis travel, and workpiece capacity, choosing a machine with an excellent tool changing system, coolant delivery system, and chip removal system can significantly enhance machining efficiency.