What is a gun drill

Gun drill is a special tool for small diameter deep hole processing, usually used for drilling holes with a diameter of 1mm-30mm and a depth-to-diameter ratio of up to 100:1 or more. Gun drill adopts a single-edge design, coolant enters through the center hole of the drill bit, and chips are discharged along the outer groove of the drill body, ensuring high-precision and efficient processing.

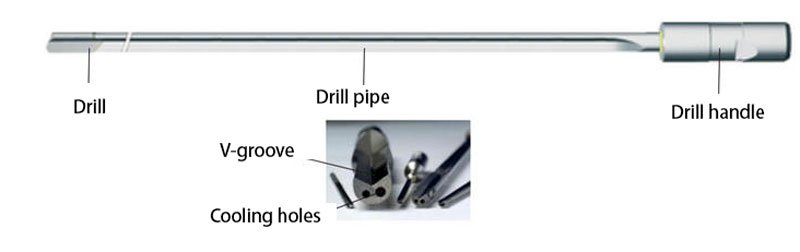

The structure of gun drill

Drill (cutting part): a drill with a single or double-edged structure to optimize chip control.

Drill rod (support part): a slender rigid rod with straight or spiral grooves for chip discharge.

Cooling system: coolant is sprayed through the center hole to lubricate the cutting area, reduce heat accumulation, and increase tool life.

Connector (tail): connects to the machine tool spindle or tool holder to ensure processing stability.

How a gun drill works

The coolant enters through the center hole of the drill rod and is sprayed directly into the drilling area, lubricating the cutting process and cooling the blade at the same time.

The blade cuts the workpiece material to form metal chips.

The chips are discharged along the external groove of the drill rod to avoid accumulation in the hole and improve processing stability.

The guide block fits the hole wall to improve the straightness and smoothness of the hole.

Features of Gun Drill

Suitable for small diameter deep hole processing

High precision, hole diameter tolerance IT7-IT9, surface roughness can reach Ra0.2-0.8μm

Suitable for hole processing with high depth-to-diameter ratio (L/D≥ 100:1).

Excellent cooling effect, avoid tool overheating and improve drilling stability.

Can process a variety of materials, such as stainless steel, titanium alloy, aluminum alloy, copper alloy, high-strength alloy, etc.

Classification of gun drills

Standard gun drill: The most common form of gun drill, which uses external chip removal and is suitable for most small hole and deep hole processing.

Double-edged gun drill: It has two cutting edges to improve chip removal efficiency and feed speed, and is suitable for deep hole processing with larger diameter.

Micro gun drill: suitable for ultra-small hole processing with a diameter of less than 1mm, commonly used for high-precision hole processing in the medical and electronics industries.

Application areas of gun drilling

Applicable to plastic molds, die-casting molds, stamping mold manufacturing, etc.

Automobile engine parts (such as crankshafts, connecting rods, fuel injection systems).

Aircraft engine nozzles, hydraulic system components, aerospace structural parts.

Medical devices, orthopedic implants (such as bone screws, intramedullary nails), injection needles, precision medical devices, etc.

Processing solution

How to choose a suitable gun drill? We at Smartlathe will provide you with a suitable processing solution. In deep hole processing, it is very important to choose a suitable gun drill and machine tool. Smartlathe DH-400 CNC deep hole drilling machine adopts high-precision guide rails, high-rigidity structure and intelligent cooling control system to ensure high-precision and high-stability processing.