What should be paid attention to when drilling holes on non-planar workpieces?

Drilling, while deceptively simple, is actually a complex process in which a drill bit malfunctioning or exceeding its capabilities can have serious consequences. Drilling non-planar workpieces may subject the cutting edge of the drill bit to excessive and uneven forces, resulting in premature wear, be sure to pay attention to the points mentioned below.

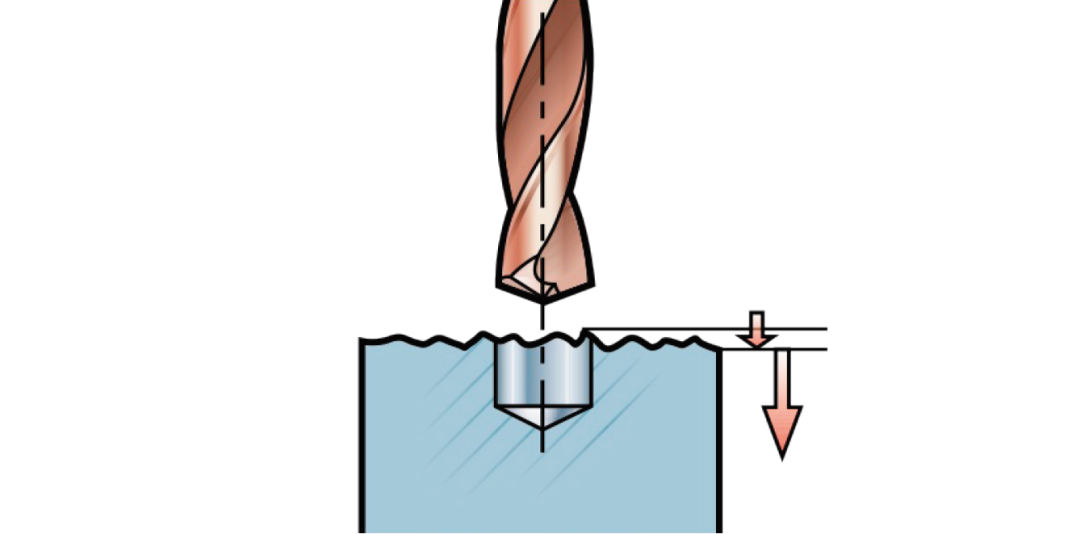

When drilling into non-flat surfaces, there is a risk of bit deflection. To avoid this, the general principle is to lower the feed while drilling.

01 Convex

Drilling is possible if the radius is greater than 4 times the drill diameter and the hole is perpendicular to the radius. Reduce feed to 50% of normal feed rate during drilling.

02 Concave

Drilling is possible if the radius is greater than 15 times the drill diameter and the hole is perpendicular to the radius. Reduce feed to 25% of normal feed rate during drilling.

03 slope

If the inclination is 10° or less, reduce the feed to 1/3 of the normal feed rate during drilling. Drilling is not recommended if the inclination is greater than 10°. First mill a small flat on the surface and then drill the holes.

04 irregular surface

Reduce the feed rate to ¼ of the normal feed rate to avoid chipping of the cutting edge.