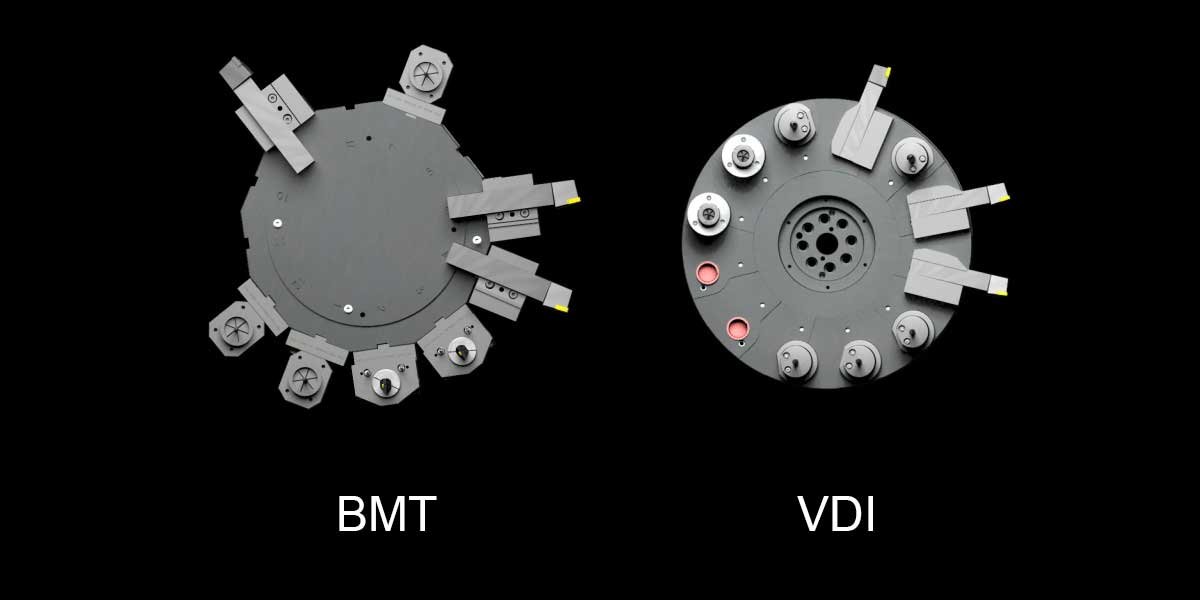

Differences Between BMT and VDI Turrets

In the field of CNC machine tools, BMT (Base Mount Turret) and VDI (Verband Deutscher Ingenieure) are two common types of turrets. They differ in terms of process, structure, precision, and operation, each suited to different machining needs. This article will provide a detailed comparison of these two turret types.

1. Structural Differences

BMT Structure

BMT turrets are directly mounted on the machine base, ensuring high rigidity and stability. This design reduces vibrations during cutting, making it suitable for heavy-duty and high-precision machining. The high level of integration in its structure means that all components fit closely together, enhancing overall stability and durability.

VDI Structure

VDI turrets use a modular design where tools are mounted in a V-shaped slot via standardized interfaces, typically reinforced with positioning pins. This design offers greater flexibility and adaptability. The modular structure of VDI allows for quicker tool changes and position adjustments. However, despite the operational flexibility, the rigidity is lower compared to BMT turrets, which may affect machining accuracy during heavy-duty cutting.

2. Operational Differences

BMT Operation

While tool change speed is slower with BMT turrets, their high rigidity and stability reduce vibrations and errors during machining, making them suitable for tasks with high precision requirements.

VDI Operation

VDI turrets have a clear advantage in terms of operation. Their modular design and standardized interfaces make tool changes and position adjustments very straightforward and quick, ideal for production environments where tools are frequently swapped. This ease of operation significantly boosts production efficiency, especially in scenarios involving multiple product types and small batch sizes.

3. Differences of process

BMT Process

BMT turrets, mounted directly on the CNC lathe base, provide exceptional rigidity and stability, suited for heavy-duty cutting and high-precision tasks. Their design effectively minimizes vibrations during machining, enhancing both quality and accuracy. The highly integrated structure of BMT turrets makes them excellent for demanding machining tasks, although tool change speeds are relatively slower.

VDI Process

VDI turrets, with their modular design, allow tools to be mounted in a V-shaped slot via standardized interfaces, which may shift due to vibrations. This modularity enables quick tool changes and adjustments, significantly improving production efficiency. However, the lower rigidity of this design under heavy-duty cutting conditions might affect machining precision. Thus, VDI is more suitable for frequent tool changes, whereas BMT excels in tasks requiring high rigidity and precision.

4. Precision Differences

BMT Precision

BMT turrets, directly mounted on the CNC lathe base, offer high rigidity and stability, excelling in heavy-duty cutting and high-precision machining. Their robust structure minimizes tool-workpiece vibrations, improving machining accuracy and surface quality.

VDI Precision

VDI turrets, with their modular design and standardized interfaces in V-shaped slots, offer high flexibility and adaptability but lower structural rigidity compared to BMT turrets. The connections between modules can lead to minor error accumulations, especially under high-load or high-speed cutting conditions, potentially impacting machining precision. Hence, BMT turrets are generally more advantageous for high-precision machining tasks.

In summary, BMT and VDI turrets each have distinct characteristics in terms of process, structure, precision, and operation. BMT turrets, with their high rigidity, precision, and stability, are suitable for heavy-duty and high-precision machining tasks. VDI turrets, with their flexibility and ease of operation, are ideal for production requiring multiple product types and small batch sizes. The choice of turret type should be based on the specific machining needs and production conditions of the CNC lathe to achieve optimal machining results and production efficiency.