Double Spindle CNC Lathe with Guide Bushing or not.

1.Function of the Guide Bushing

The guide bushing in a Swiss-type lathe is used to guide and support the workpiece, ensuring its stability during the machining process and reducing vibration and displacement.

Due to the bending of the material or the forces generated during machining, if the machining part is far from the material clamping position, achieving high-precision cutting becomes difficult. Therefore, to machine long and slender products, a mechanism to support the material (the guide bushing) is installed between the chuck and the tool, allowing the chuck to move longitudinally along the material. Since the guide bushing supports the material near the tool, it reduces the bending of the material caused by machining forces, allowing high-precision machining with a Swiss-type lathe.

2.Types of Guide Bushings

Rotating Guide Bushing: The rotating guide bushing is connected to the spindle through an intermediate coupling and can rotate synchronously with the spindle. It is suitable for machining workpieces with a length-to-diameter ratio greater than 3.

Advantages: It has lower requirements for material straightness; the guide bushing rotates together with the material, which minimizes friction in the direction of rotation, preventing jamming during high-speed machining.

Disadvantages: It has a relatively high cost; the remaining tailstock material is longer, leading to material waste; machining accuracy is lower compared to a fixed guide bushing.

Fixed Guide Bushing: The fixed guide bushing does not rotate with the spindle (material). It is also suitable for machining workpieces with a length-to-diameter ratio greater than 3.

Advantages: It has higher requirements for material straightness; it offers better machining accuracy compared to a rotating guide bushing.

Disadvantages: The remaining tailstock material is longer, leading to material waste; since the guide bushing does not rotate with the material, friction can occur in the rotational direction, which generally requires an oil film between the guide bushing and the material for lubrication.

Depending on different machining needs and requirements, choosing the appropriate Swiss-type lathe guide bushing process is crucial. If high precision and surface quality are required, and the workpiece diameter is larger than the guide bushing inner diameter with high machining volume, a non-rotating process is recommended for higher efficiency and better product quality. For smaller diameters or longer workpieces, the rotating process is preferred due to its flexibility and efficiency.

3.Components of a Double Spindle Swiss Lathe with Guide Bushing

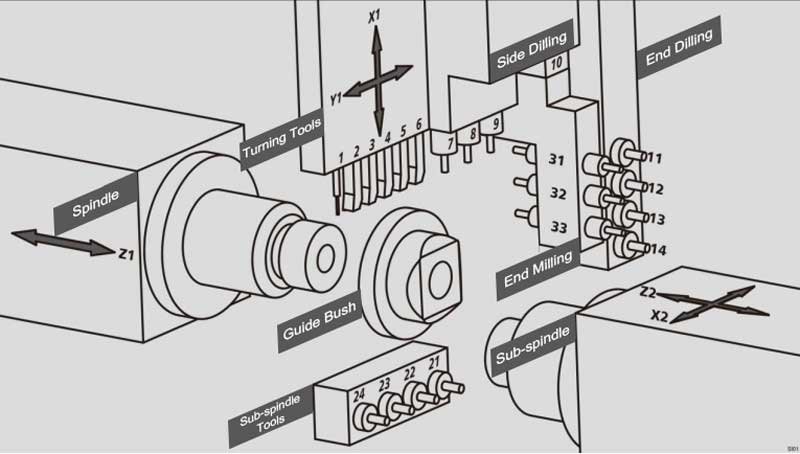

A double spindle Swiss lathe with guide bushing consists of many parts, including the tool holder, spindle, side milling, end drilling, end milling, rotating guide bushing, sub-spindle, and specialized tools for the sub-spindle.

4.Double Spindle Swiss Lathe with and without Guide Bushing

With Guide Bushing:

Structural Design: The guide bushing guides and supports the workpiece, ensuring stability and precision during machining.

Machining Accuracy: The presence of the guide bushing allows better control of workpiece movement, achieving high precision machining. In high-speed machining, the guide bushing effectively reduces vibration and displacement.

Adaptability and Flexibility: Suitable for machining complex shapes and high-precision parts, it can handle a wide range of materials and is widely used in industries such as automotive and aerospace.

Cost and Return on Investment: The investment is relatively high, but due to its high efficiency and precision, it quickly pays for itself in mass production, making it suitable for large-scale manufacturing needs.

Without Guide Bushing:

Structural Design: The workpiece is held only by the spindle, and the spindle's rotation directly affects the workpiece's stability.

Machining Accuracy: Accuracy is relatively lower. Without the support of the guide bushing, vibration may occur during machining, increasing errors, especially when machining small or complex workpieces.

Adaptability and Flexibility: More suited for simple part machining. Complex part machining may face challenges, and adaptability is relatively lower.

Cost and Return on Investment: The investment is lower, making it suitable for small-scale or simple part machining. However, in the long term, due to limitations in efficiency and accuracy, overall costs may be higher.

Conclusion: Overall, the double spindle Swiss lathe with a guide bushing offers significant advantages in machining precision, efficiency, and adaptability, especially in complex part machining. On the other hand, the guide bushing-free lathe is more suitable for low-cost production of simple parts, with a narrower range of applications. Selecting the appropriate machine type is critical.

5.Setting Guide Bushing Mode on SYNTEC Double Spindle Swiss Lathe

On the SYNTEC system control panel, find the "Parameter Settings" option and click it.

Enter the parameter settings panel, navigate to parameter number 3405, and find the R85 guide bushing switch. Set it to 0 for guide bushing mode and 1 for non-guide bushing mode.

6.Applicable SYNTEC Double Spindle Swiss Lathe Models

SW-205; SW-266; SW-326. Through the design of the double spindle and the high-precision guide bushing structure, these machines can effectively improve machining stability and efficiency, meeting the modern manufacturing industry's demands for high efficiency, precision, and multifunctionality, while reducing production costs.