Vibration Damping Principle of Cast Iron

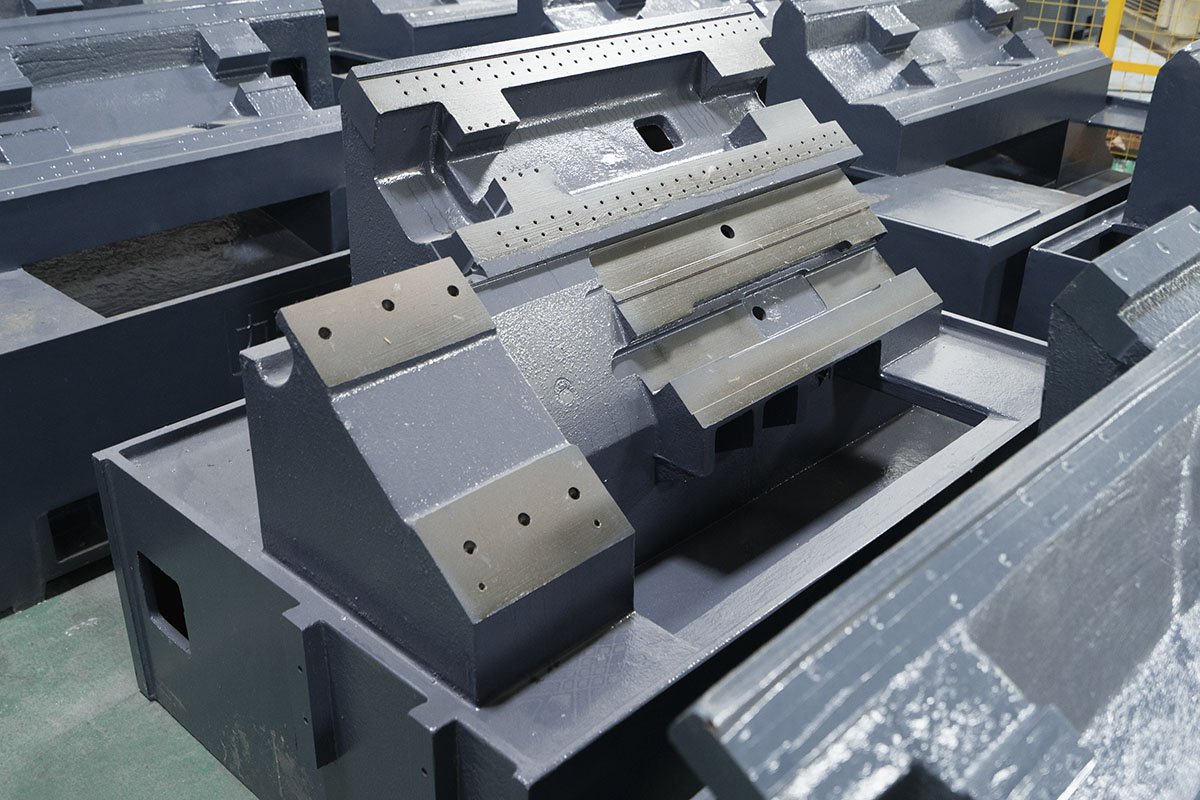

The material selection for the base of a CNC lathe is critical for ensuring the stability and precision of the machine. Commonly used materials for the base include cast iron, steel, and concrete. The base provides high rigidity and stability, absorbing vibrations during machining to ensure processing accuracy. The design of the base ensures the overall stability of the machine, reducing thermal and mechanical deformation, thus enhancing the machine's lifespan and machining quality.

Considering that CNC lathes prioritize stability and require strong vibration damping, cast iron is typically chosen for the base over steel. This is often achieved through integral molding, reducing the need for welding and assembly processes, lowering manufacturing costs, and improving production efficiency.

1.Types of Cast Iron

The cast iron used for CNC lathe bases is generally divided into two types: gray cast iron and ductile iron.

1.1 Gray Cast Iron

Advantages: High rigidity and high damping capacity, effectively absorbing vibrations to ensure machining accuracy. It also has good thermal stability, maintaining dimensional stability under temperature changes, and high wear resistance.

Disadvantages: Heavy weight, which increases the overall weight of the machine. It also has lower toughness, making it prone to breaking under impact.

1.2 Ductile Iron

Advantages: Higher strength and toughness compared to gray cast iron, with stronger impact resistance. It also maintains good vibration damping and thermal stability.

Disadvantages: Heavier weight compared to gray cast iron, making the base heavier.

By choosing cast iron, especially gray or ductile iron, for CNC lathe bases, manufacturers can achieve the necessary balance of rigidity, stability, and vibration damping needed for high-precision machining.

2.Vibration Damping Principle of Cast Iron

Utilizing the damping characteristics of cast iron to achieve vibration damping in CNC lathe bases is crucial for certain equipment. Vibration not only causes noise but can also lead to malfunctions and failures. If vibrational energy accumulates without adequate dissipation, it leads to increased amplitude. Excessive vibration can reduce the precision of precision machinery, cause instability due to wear on mating surfaces, and result in excessive wear on gears and bearings. Using components made from materials with high damping capacity can reduce vibration and noise, improve operating conditions, and extend the lifespan of the equipment.

The diagram compares the damping characteristics (vibration amplitude decay over time) of three different materials: gray cast iron, ductile iron, and steel. It can be seen that the relative damping capacity of ductile iron is approximately twice that of steel, while gray cast iron has roughly twice the damping capacity of ductile iron.

Even when isolated from external influences, a vibrating solid will gradually dissipate its mechanical vibrational energy due to internal causes, a phenomenon known as internal friction. The dissipation of mechanical vibrational energy is accomplished through internal mechanisms, which are closely related to the material's microstructure and defects, as well as to external physical parameters such as temperature, frequency, stress amplitude, and applied electric or magnetic fields. Internal friction can be represented as a function of these external parameters, resulting in a series of discrete or continuous spectra known as internal friction spectra.

The diagram shows the internal friction spectra of graphite, gray cast iron, and pure iron. From the graph, we can see that gray cast iron has a typical internal friction spectrum, with a significant increase in internal friction between 180 and 250K. Comparing the internal friction spectra of gray cast iron with its two constituents, iron and graphite, it is evident that there is a correlation between the internal friction spectra of gray cast iron and graphite. This indicates that the graphite phase is the source of internal damping in gray cast iron, with energy dissipation arising from dislocation movements on the basal planes of the graphite.

With its predominantly spheroidal graphite structure, dissipates vibrational energy less effectively than the flake graphite structure in gray cast iron. However, ductile iron's mechanical properties, such as strength and toughness, are much closer to steel and significantly better than gray cast iron. Therefore, ductile iron is more commonly used in critical applications that require both vibration damping and high mechanical performance. In less critical applications where vibration damping is more important and the load is not too significant, gray cast iron, with its superior damping effect, is preferred.