How many kinds of the tool setting methods you know

Tool setting of CNC lathe is an important skill in processing. The accuracy of tool setting determines the machining accuracy of parts. The efficiency of tool setting directly affects the processing efficiency of parts. Tool setting is very important to the machining operation of machine tools.

How to judge processing by cutting

In metal cutting, some chips are rolled into coils and break off when they reach a certain length; some chips are broken into C-shaped and 6-shaped; splashing around, affecting safety; some strip-shaped chips are wrapped around the tool and workpiece, which is easy to cause accidents. Poor chip removal status will affect the normal production. The use of chuck soft jaw.

What are the spindles of CNC lathes?

CNC lathe is a kind of mechatronics equipment with high comprehensive performance. For CNC lathe, it has some advantages. Its processing precision is very high, which can improve production efficiency, reduce labor intensity of workers, and promote the comprehensive processing of processing enterprises. It is precisely because of these advantages that it has been widely used in many manufacturing fields. Whether the choice of CNC machine tools is reasonable is closely related to the processing quality and production efficiency. Undesirable effects due to normal processing.

The Introduction of The Auxiliary for CNC Lathe Machine

The optional auxiliary for a CNC lathe can vary depending on the specific machine and its configuration. However, some common optional auxiliaries that can be added to a CNC lathe for enhanced functionality and capabilities.

What are the operations performed in a CNC lathe?

Obviously, CNC lathe is the most popular Lathes on the market, and let’ study more about it. CNC means Computerized numerically controlled, which is widely used as a lathe in modern society because of its fast and accurate working.

The machine tool is controlled by computer programs. Once the program is loaded into the computer, it begins to operate at a high rate and with great accuracy. Even a preplanned programmed machine exists, in which once the code for the various tasks is set, the machine may begin operating without having to change the code again. After the initial setup, a semi-skilled worker may readily run it. These sorts of lathes, like capstan and turret, are also utilized for mass manufacturing, but there is no programmed feeding system. These lathes produce components with extremely tight dimensional tolerances.

What is CNC Lathe?

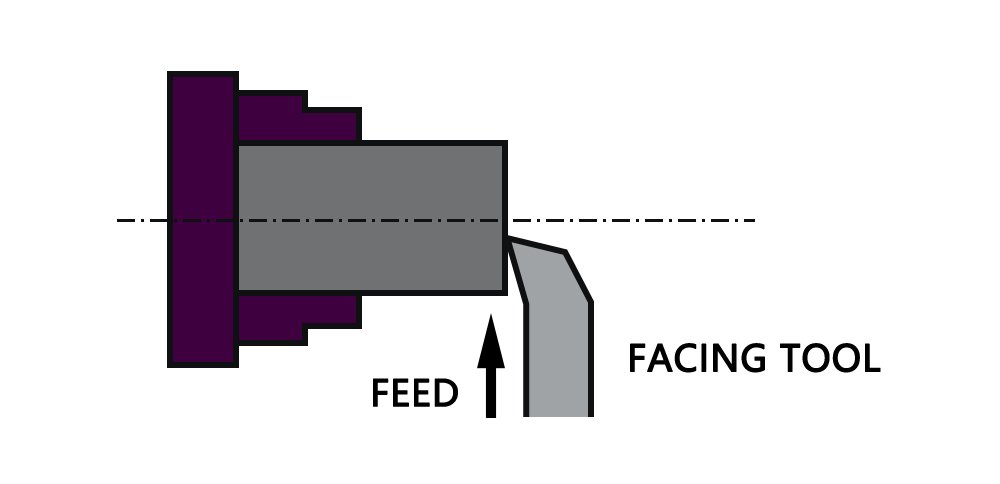

CNC lathe is a computer-numeric controlled machine tool specialized in CNC turning machining, including taper turning, hard turning, spherical generation, facing, cutting off, knurling, drilling, grooving, etc. Compared to a conventional lathe, CNC lathes are operated with precise design instructions and programs to improve the productivity and precision of CNC machining demands.