Types and uses of CNC lathe tools

The turning tool is the most widely used single-edged tool, and it is also the basis for learning and analyzing various tools. Turning tools are used on various lathes to process outer circles, inner holes, end faces, threads, grooves, etc. According to the structure, turning tools can be divided into integral turning tools, welding turning tools, machine clamp turning tools, indexable turning tools, and forming turning tools. Among them, the application of indexable turning tools is becoming more and more extensive, and the proportion of turning tools is gradually increasing.

What is the difference between a CNC lathe and a CNC milling machine?

CNC lathes and CNC milling machines are both CNC machine tools. Both machine tools use programs to specify their tool paths. The following is the difference between the two in terms of working principles and uses.

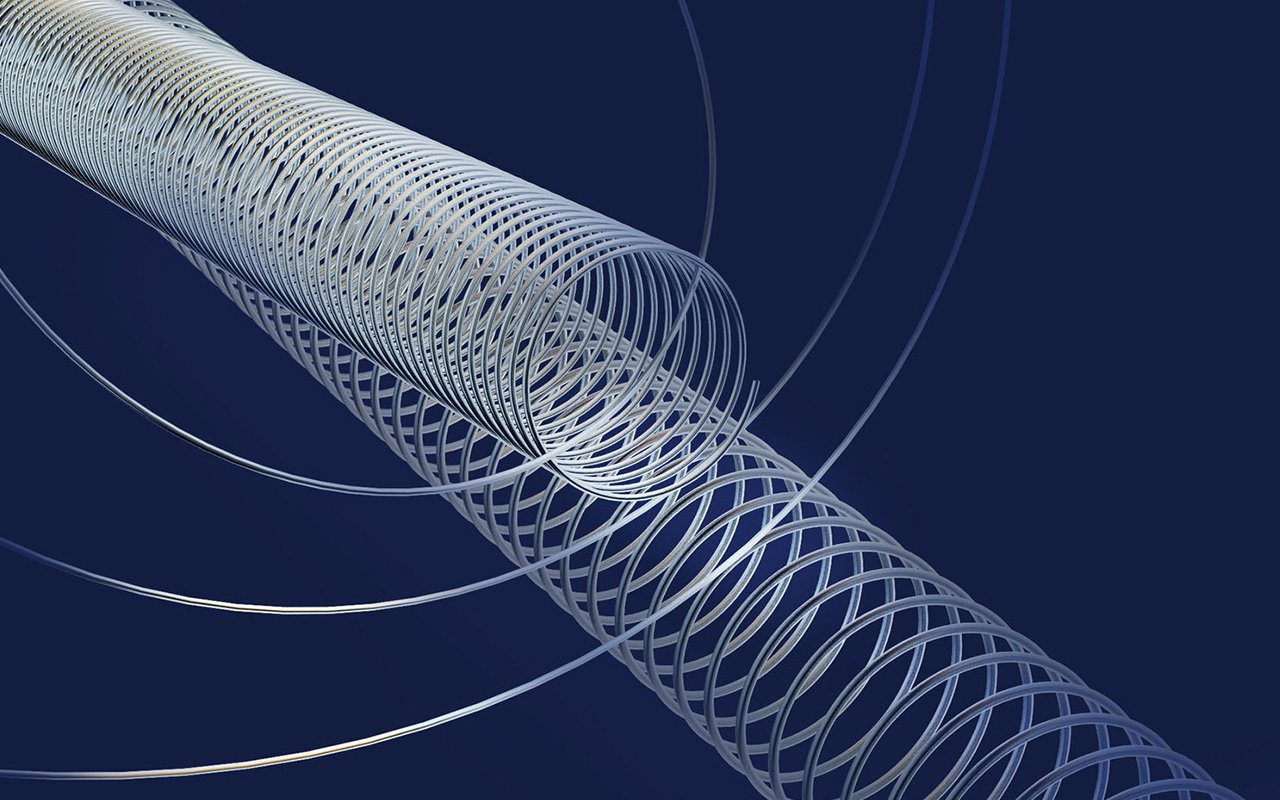

Three special functions of titanium

It refers to the ability of Ti-50%Ni (atomic) alloy to restore its original shape under certain temperature conditions. This material is called shape memory alloy.

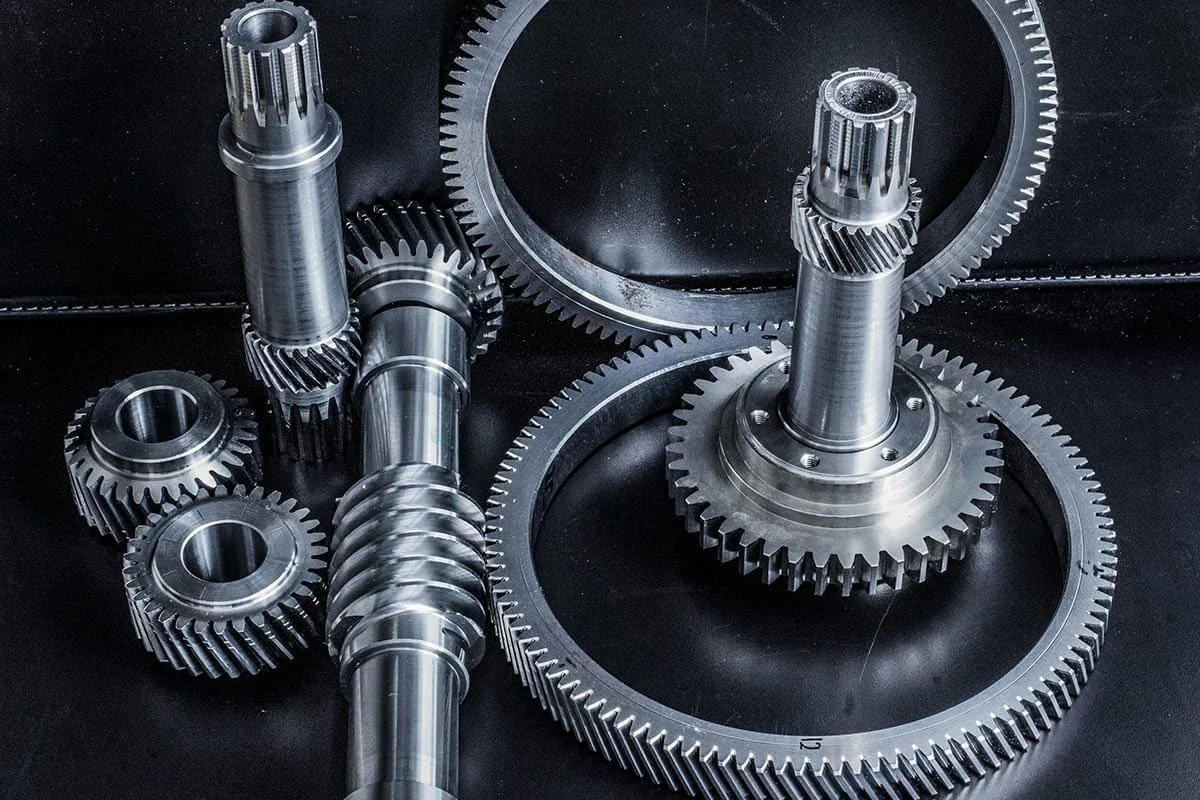

Turning, milling, planing, grinding, drilling, boring, what kind of precision can be achieved

The workpiece rotates, and the turning tool moves in a straight line or a curved line in the plane. Turning is generally carried out on a lathe to process the inner and outer cylindrical surfaces, end surfaces, conical surfaces, forming surfaces, and threads of the workpiece.

These parts are really hard to measure. What should I do?

Standard measuring tools such as micrometers or calipers are commonly used "tools" for measuring flat and parallel features or inner/outer diameters of workpieces. However, when measuring workpieces with complex shapes, such as curved surfaces or narrow grooves, it may be difficult for standard universal measuring tools to reach the accurate measurement position. It is relatively easier and more economical to choose dedicated non-standard measuring tools.

How to Calculate CNC Speed and Feed

Each tool will adopt different processing parameters for different processing materials. In the field of milling, tool manufacturers develop more targeted coating technologies by optimizing tool materials to improve processing efficiency.

Through the combination of various elements in the material, we can see thousands of machinable raw materials. To process these materials, we must know the processing performance of this material, and also know the method that should be optimized for processing.

10 properties of titanium

Titanium is an element with an atomic number of 22 in the periodic table. It is a subgroup element of the fourth period, namely group IVB. In addition to titanium, this group of elements also includes zirconium and hafnium. Their common feature is that they have a high melting point and can be dissolved on their surface at room temperature. Form a stable oxide film.

In CNC milling, down milling or up milling?

In CNC machining, the rotation direction of the milling cutter generally remains unchanged, but the feed direction changes. There are two common phenomena in milling processing: down milling and up milling.

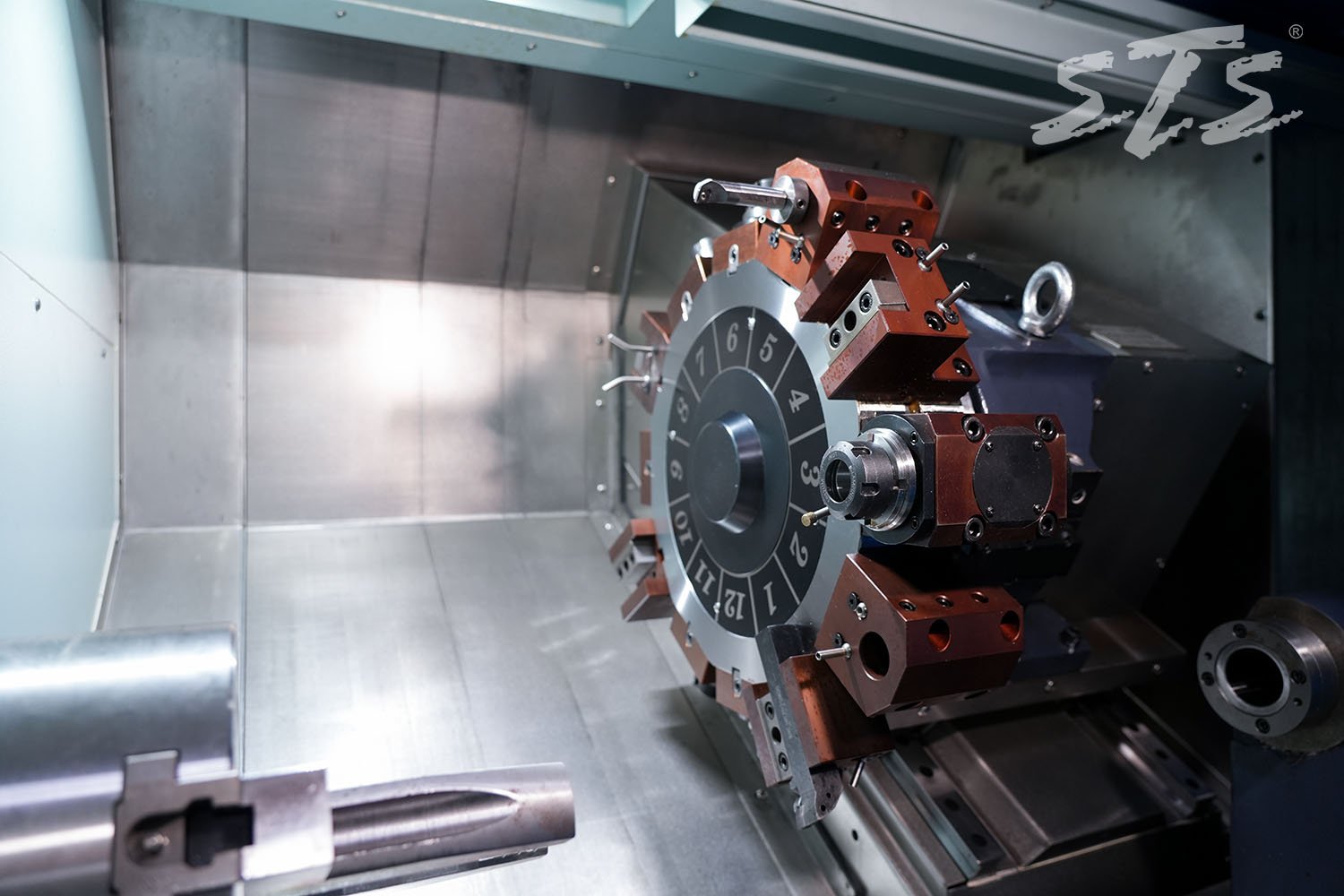

Wedge-Type Y-Axis CNC Lathe VS Real (True) Y-Axis CNC Lathe

Wedge-Type Y-Axis CNC Lathe: The wedge-type Y-axis mechanism utilizes a wedge block to position the tool off-center, enabling Y-axis movement. It allows for off-center drilling, milling, and other complex machining operations.

Real (True) Y-Axis CNC Lathe: A true Y-axis CNC lathe incorporates a dedicated Y-axis that enables vertical movement of the cutting tool perpendicular to the spindle axis. This provides precise control over the Y-axis movement and offers increased versatility in machining operations.

Why are tools deliberately "dulled"?

Isn’t the faster the CNC tools used in machining centers, the better? Why do they need to be passivated? In fact, tool passivation is not what everyone understands literally, but a way to increase the service life of tools. Improve tool quality through processes such as smoothing, polishing, and deburring. This is actually a normal process after the tool is finely ground and before coating.

What precision tolerance levels can be achieved for various machining processes?

We deal with machining every day. Do you know what precision tolerance levels can be achieved in turning, milling, planing, grinding, drilling and boring?

Tolerance level refers to the level that determines the degree of dimensional accuracy. The national standard stipulates that it is divided into 20 levels, from IT01, IT0, IT1, IT2 to IT18. The larger the number, the lower the tolerance level (processing accuracy), and the allowable variation range of size (tolerance The larger the value), the less difficult it is to process.

Product parts require different processing accuracy depending on their functions, and the selected processing forms and processing techniques are also different. This article introduces the machining accuracy that can be achieved by several common processing forms such as turning, milling, planing, grinding, drilling, and boring.

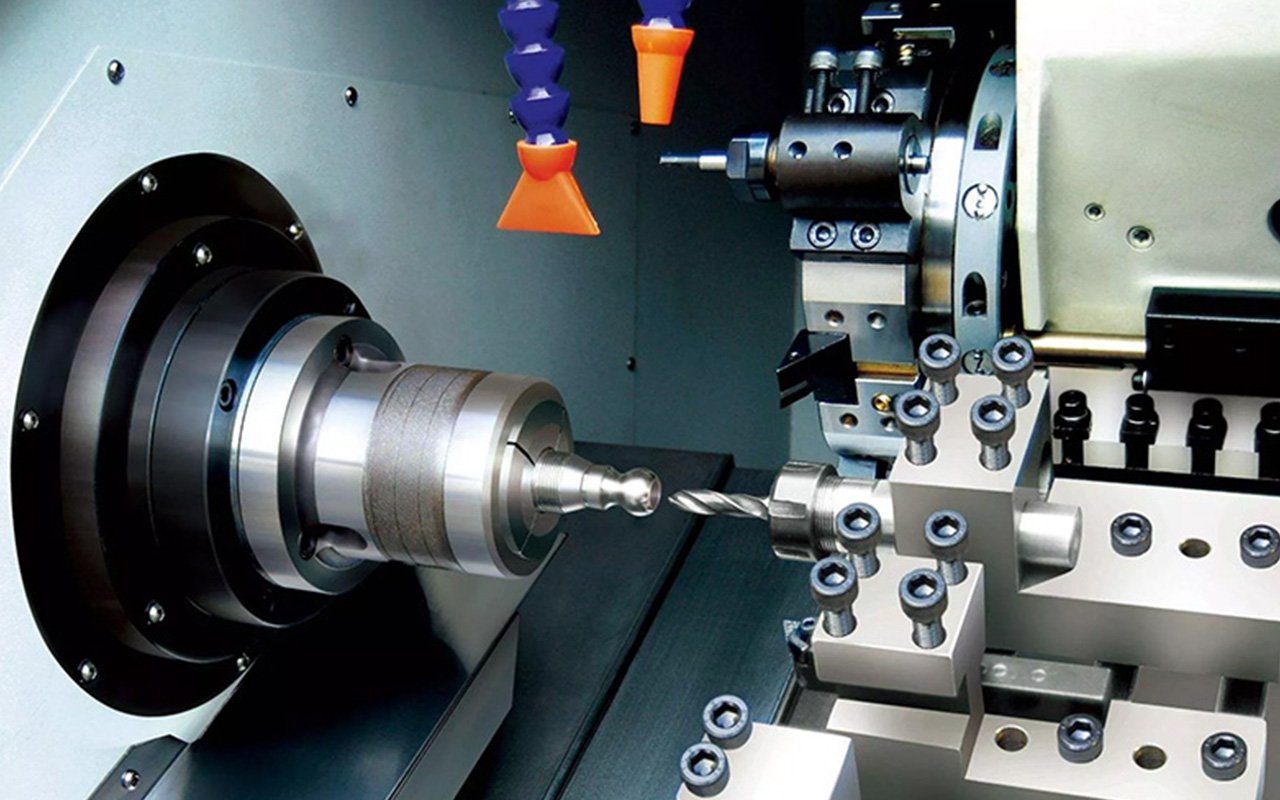

CNC lathe tool shape and usage

The types of turning tool tips generally used are as follows: Rough turning tools, Fine turning tools, Round nose turning tools, Threading tools, Boring turning tools, End face turning tools and Parting off tools.

How to solve the problem of tool vibration in machining

When the force is applied, if the tool is not rigid enough, the tool body will deform, and a deviation will be produced in the direction of the force, and there will be a displacement. The tool has a displacement, so the depth of the knife will be smaller, the force will be smaller, and the displacement will be smaller. The generated displacement becomes smaller, and the tool moves in the opposite direction of the force, so that the cutting depth becomes larger, and the cutting becomes larger at the same time.

This is like comparing a tool to a long and thin wooden stick. One end is fixed and the other end is stressed, so the end away from the unfixed end will be deflected and rebound.

In this way, during the machining process, constantly changing cutting forces act on the tool and the workpiece, resulting in vibrations.

How to drill a perfect hole

Chip formation and chip evacuation are key issues in drilling and depend on workpiece material, choice of drill/insert geometry, coolant pressure/volume, cutting parameters.

How to choose a drill bit for drilling?

Drilling processing, there are three basic conditions for selecting a drill bit: material, coating and geometric characteristics.

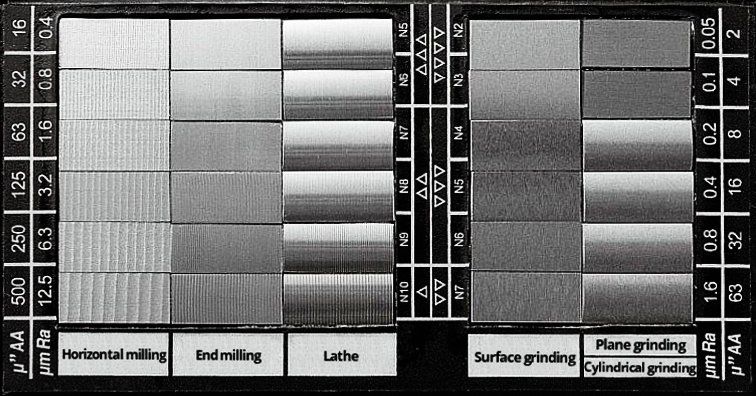

Do you really understand surface roughness?

In factory communication, many people are accustomed to using the term "surface finish". However, "surface finish" is proposed from the perspective of human vision. In order to conform to the international standard (ISO), the national standard no longer uses the term "surface finish". Therefore, in formal and rigorous expressions, the word "surface roughness" should be used.

Surface roughness refers to the small spacing and the unevenness of small peaks and valleys on the machined surface. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic geometric shape error. The smaller the surface roughness, the smoother the surface.

CNC lathes are capable of turning not only circles but also polygons.

Tool with two insets are used to cut quadrilaterals, and with three insets are used to cut hexagons, etc. If a different gear ratio is used or if the number of cutting edges of the tool is changed, large depressions or prominent deflection arcs may appear on the workpiece surface.

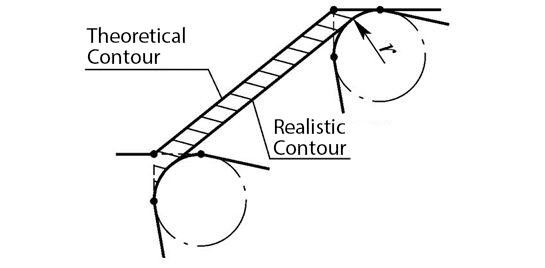

Tool Compensation Function for CNC Lathe Machining

In the process of NC programming, in order to make the programming work more convenient, the tip of the NC tool is usually imagined as a point, which is called the tool point or tool tip point.

According to the actual size of the tool, the CNC machine tool automatically changes the coordinate axis of the machine tool or the position of the tool tool point, so that the actual machining contour and the programmed trajectory are completely consistent, which is called tool compensation ("tool compensation" on the system screen) function.

Manufacturing method of soft jaws of CNC lathe chuck

The chuck soft jaw of CNC lathe is a device for clamping the workpiece. It is a relatively soft jaw that has not been heat-treated, and can be processed according to the shape of the workpiece to improve positioning accuracy²³. Soft claws have different specifications and shapes, such as 6" soft claws, 8" soft claws, 10" soft claws, thickened, widened, square, pointed soft claws, etc.

What should be paid attention to when drilling holes on non-planar workpieces?

Drilling, while deceptively simple, is actually a complex process in which a drill bit malfunctioning or exceeding its capabilities can have serious consequences. Drilling non-planar workpieces may subject the cutting edge of the drill bit to excessive and uneven forces, resulting in premature wear, be sure to pay attention to the points mentioned below.