The processing technique of controlling roughness by controlling cutting parameters for materials of different hardness

In metal turning processes, the surface roughness of metal is influenced by numerous variables. Today, we're discussing how surface roughness is affected by different cutting parameters for metals of varying hardness when other variables remain constant.

What is turn-milling combination?

The names of various CNC lathes steadily get more cryptic as the variety of lathe types grows. We will then go over what a CNC turn-mill combination is. Prior to comprehending the CNC turn-mill combination, it is important to first comprehend the CNC lathe and CNC milling machine independently and determine their prior differences.

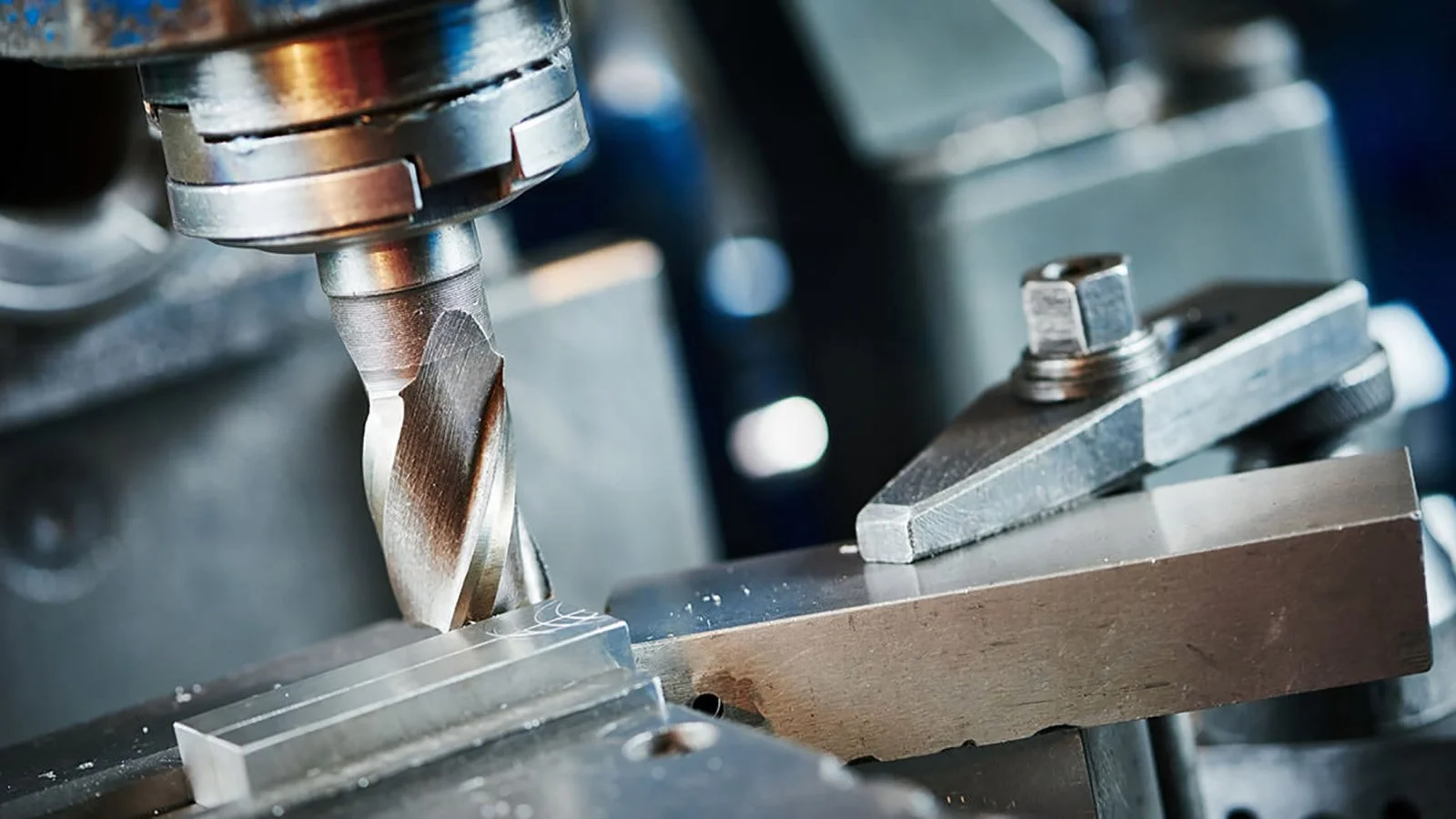

Turning vs Milling: What’s the Difference?

To put it simply: lathes are round, milling machines are flat. In lathe operations, the cutter is stationary while the workpiece rotates. The workpiece does not revolve during milling machine processing; instead, the tool rotates.

What is ER collet with CNC lathe

The subtype of chuck known as a collet is a cylindrical sleeve. With a pointed outer surface and a tube-shaped inner surface, the sleeve is used to create a collar around a tool or gadget. Collets have a conical outer surface that often provides a strong gripping force on the thing they are grasping when tightened.

What’s the information that we can get from the drawings?

As the professional CNC lathe supplier, we always to recommend the suitable CNC lathe model with related configuration base on customized drawings of jobs.

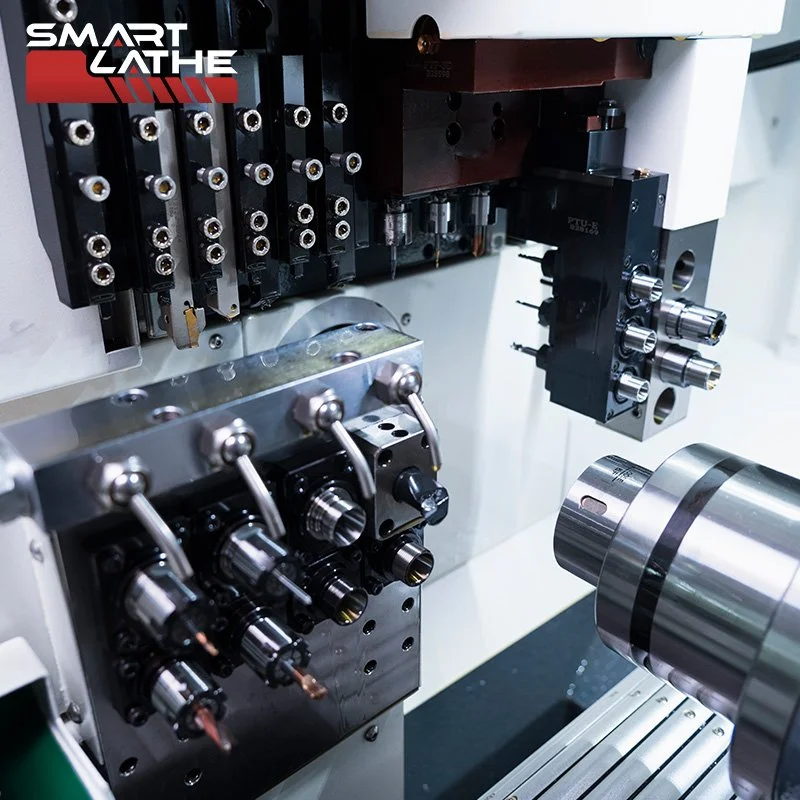

Exploring the Versatility of Power Turret

The power turret, a prevalent feature in CNC machine tools, combines turning and milling capabilities. It boasts multiple mounting planes and slots along its circumference for attaching various tool holders, including turning, boring, 0-degree power, 90-degree power, right-angle internal retracting power, eccentric power, and dual-spindle output tool holders.

Comparing Three-Phase Induction Motors and Servo Motors, Which Is the Better Choice?

In modern industrial manufacturing, motors are crucial for driving equipment, with three-phase induction motors and servo motors being common choices. They differ significantly in performance, application, and benefits. This article will compare the two types, aiding your understanding of their pros and cons in CNC lathe applications.

Analysis of Conversational Programming and Graphics Support Functions of Multiple CNC Lathe Operating Systems

In the increasingly competitive landscape of manufacturing, the efficiency and accuracy of CNC programming are crucial for production processes. To meet this demand, several CNC system providers have introduced conversational programming and graphical support features to enhance users' programming experience and production efficiency. This article provides an overview of seven major CNC system: Fanuc, Siemens, SYNTEC, Beijing-Fanch, GSK, KND, and HNC. So that you can understand the characteristics of different CNC systems and choose the system that is suitable for your CNC lathe.

A Comprehensive Chronicle of the ST-46YTC CNC Lathe Project – From Client Vision to Shipment Perfection

Client’s requirement: The client provides detailed requirements for the workpiece and machine.

Enhancing CNC Lathe Efficiency with Chip Conveyor

A chip conveyor is a machine primarily utilized to gather various metal and non-metal waste produced by machinery and transfer it to a collection vehicle. It contributes significantly to maintaining a clean work environment, reducing manual labor, and preventing chip interference with machining operations. And it can easily collect metal waste.

Choice of Automatic Bar Feeder for CNC Lathes, Oil Bath Bar Feeder, or Servo Bar Feeder?

CNC lathe automatic feeder refers to a feeding machine that cooperates with a CNC lathe that can continuously process materials to achieve automatic feeding, thereby improving the processing efficiency and automation of the equipment.

Oil bath bar feeders and servo bar feeders are common automatic feeding equipment, and they have different working principles and features.

What is a Swiss Type CNC Lathe?

A Swiss-type CNC machine, also known as a Swiss-type lathe or Swiss automatic lathe, is a high-precision machine tool designed for machining small, complex parts. It has gained recognition in the manufacturing industry for its outstanding precision machining capabilities and efficiency.

The working principle of Swiss-type CNC lathe tools is guiding a long metal rod through supporting components and securely holding it in place as it enters the cutting area of the machine. Only the portion of the metal rod that requires machining moves into the cutting area, ensuring stability and accuracy.

Ordinary CNC lathe machined workpieces remain stationary and rotate rapidly, with one or both ends of it being tightly fixed. But with a Swiss-type CNC lathe, the workpiece can rotate and move back and forth on the Z-axis as the tool forms it. Swiss-type CNC lathe can do many tasks in different areas at the same time.

Optimizing CNC Lathe Machining Processes with Fusion 360 Post-processing

CNC lathes are indispensable in modern manufacturing, and Fusion 360's post-processing capabilities offer new avenues for efficiency and innovation in the machining process. Whether you operate a small workshop or a large-scale manufacturing facility, using Fusion 360 to handle CNC lathe stuff can help you get awesome results.

What function does the tailstock serve in the CNC machining process?

Whether a tailstock is required when using a CNC lathe to machine a workpiece depends on the length of the piece. Short-length pieces can be machined without a tailstock. However, for accurately machining long, slender pieces such as a rifle barrel without distortion or chatter, a tailstock is essential to the CNC machining process.

How to Reduce or Fix CNC Machine Chatter?

After turning on a mechanical lathe, a tail nail may appear, an effect caused by the lathe stopping at the end of the workpiece. In the machining world, the tail nail is often referred to as a "chatter mark" or "chatter". This is because when tail nails form on the surface of a workpiece, they create a vibrating or trembling effect, similar to a "chatter" sound. Therefore, you can use these two terms to describe this tail nail phenomenon that occurs in lathe processing.

Chatter during machining will reduce tool life and a substandard surface finish.

Cutting fluids for CNC machining processes

A cutting fluid is a substance designed specifically for metal-working and machining processes where it acts as a coolant and lubricant. This fluid is applied while the machining is being done. Application methods for cutting fluids include flooding, fluid jetting, mist spraying, etc.

What is CNC cutting fluid and the Functions of Cutting Fluid During CNC Machining

CNC machining is a subtractive manufacturing technology where a cutting tool attached to a spinning spindle removes material from the workpiece, to accomplish the required machining operation.

The Significance of CAM Post Processors and the Most Popular Post Processors

Machine design and control are accomplished using CAD and CAM technologies. Machines require post-processors to make sure the code that is provided to them is readable and understandable and to maximize machine performance.

A Set of Pictures to Help You Understand the Common Methods of Machining

The key of turning is to rotate the workpieces to be processed, and then move the linearly moving tool close to them to carve the surface of the workpiece.

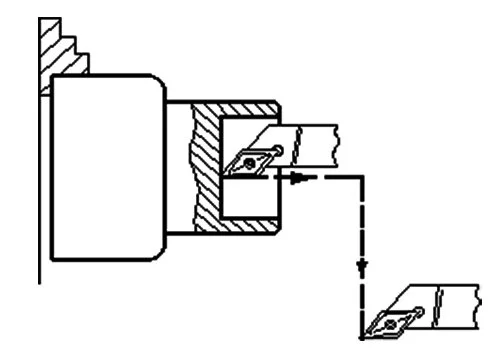

Three methods of retracting the turning tool of CNC lathe

In the process of CNC machine tool processing, in order to improve the processing efficiency, the tool moves from the starting point or tool change point to the position close to the workpiece and returns to the starting point or tool change point after processing in G00 (rapid point positioning) mode. The principle of considering the tool retraction route is: first, to ensure safety, that is, not to collide with the workpiece during the tool retraction process; second, to consider the shortest tool retraction route, shorten the empty stroke, and improve production efficiency.