How to Properly Choose a Dual-Spindle CNC Lathe

Choosing a dual-spindle CNC lathe involves considering material specifications, processing requirements, CNC system reliability, and the manufacturer’s capacity for long-term technical support and after-sales service. If you're uncertain about which model suits your needs, you can contact SMARTLATHE's sales team. By providing your drawings and requirements, SMARTLATHE will assess the best model for you and also offer sample services and on-site equipment installation and debugging to support your manufacturing process.

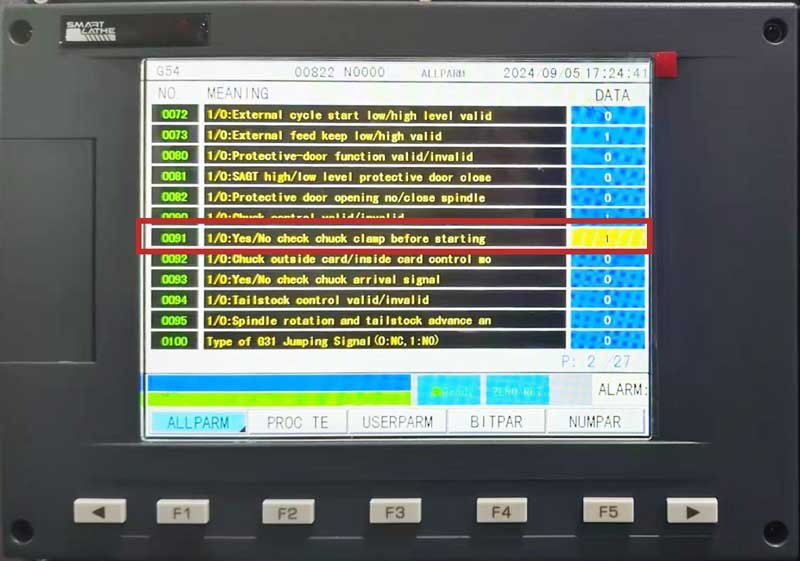

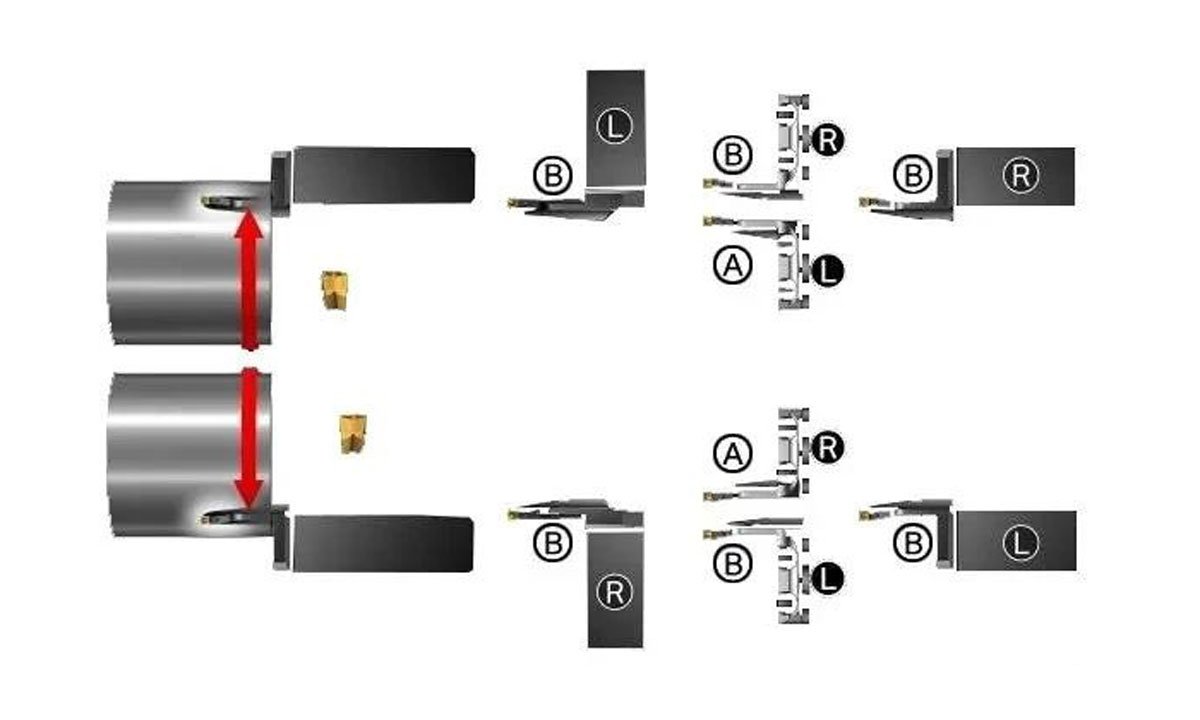

Smartlathe Brain System Chuck Clamping Mode Switch: Internal and External Clamping

In the daily CNC lathe production process, it is often necessary to change the chuck clamping method depending on the workpiece clamping needs. The smartlathe brain CNC lathe control system sets the parameters for switching between internal and external clamping. It is possible to quickly switch between the clamping methods by changing only one parameter setting.

Twin-Spindle Swiss-Type Lathe: A Key Tool for Precision Manufacturing in the Future

In modern manufacturing, with the increasing diversity and complexity of product demands, the requirements for machining equipment have also risen. The twin-spindle Swiss-type lathe, as a high-efficiency, precision machining tool, is gradually becoming the preferred choice in many high-end manufacturing sectors. It represents not only a technological innovation but also a crucial tool for driving production efficiency and improving product quality.

The SW-266 twin-spindle Swiss-type lathe is a high-performance CNC lathe meticulously developed by our company, designed specifically to meet the needs of modern manufacturing for high-efficiency, high-precision machining. This model integrates advanced technology and innovative design concepts, offering users excellent machining capabilities and flexible production solutions.

Key Choices for Boosting Production Efficiency: Twin-spindle with Single Turret vs. Twin-spindle with Twin-turret CNC Lathes

In modern manufacturing, selecting the right CNC lathe not only significantly enhances production efficiency but also optimizes production costs. For businesses that prioritize high precision and efficiency, the twin-spindle single turret DS-6146SY and twin-spindle twin turret DS-4636DTY CNC lathes have become mainstream options. However, how do you make the best choice between the two? This article will deeply analyze the advantages and application scenarios of these two types of equipment to help you make an informed decision.

Tolerance Compensation for Twin-Spindle CNC Lathe

Tolerance compensation is divided into thermal compensation and geometric compensation. The machine tool has a compensation system primarily composed of a microcomputer integrated with the machine tool controller.

The compensation value is calculated by the microcomputer based on the temperature signals from the machine tool and the worktable's motion position signals, combined with the comprehensive Tolerance mathematical model. The value is then sent to the machine tool controller to provide additional feed movement to the tool carriage for real-time compensation.

The main sources of thermal Tolerance in machine tools are the motor, bearings, transmission parts, hydraulic systems, and external and internal heat sources such as environmental temperature. These sources cause thermal deformation in the machine components. These Tolerances can be reduced by improving the machine structure during design and manufacturing. However, in most cases, machine Tolerances cannot be reduced by design and manufacturing techniques alone.

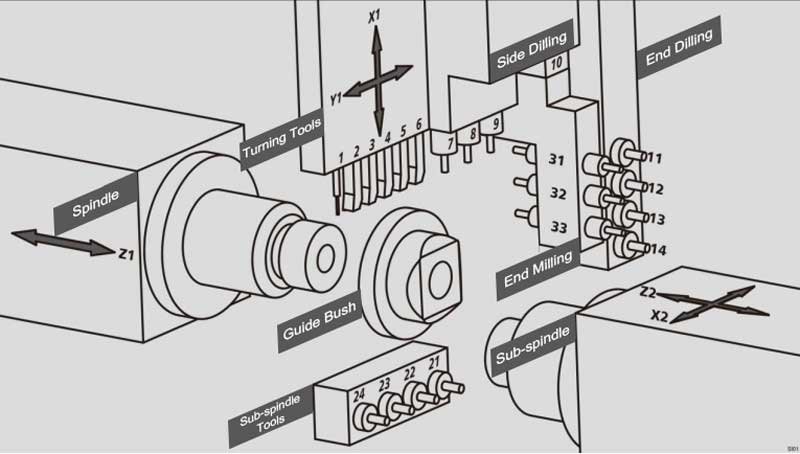

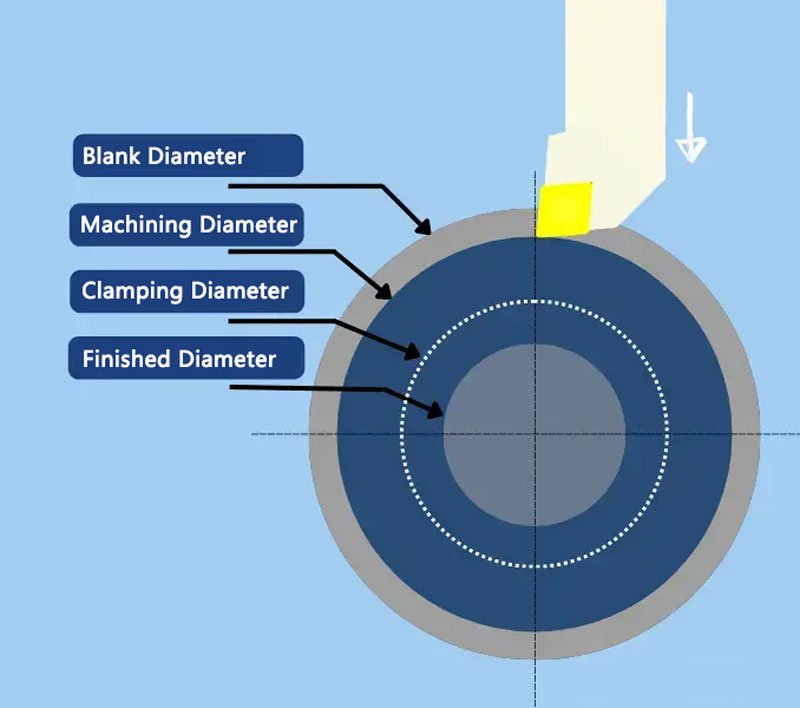

Double Spindle CNC Lathe with Guide Bushing or not.

The guide bushing in a Swiss-type lathe is used to guide and support the workpiece, ensuring its stability during the machining process and reducing vibration and displacement.

Due to the bending of the material or the forces generated during machining, if the machining part is far from the material clamping position, achieving high-precision cutting becomes difficult. Therefore, to machine long and slender products, a mechanism to support the material (the guide bushing) is installed between the chuck and the tool, allowing the chuck to move longitudinally along the material. Since the guide bushing supports the material near the tool, it reduces the bending of the material caused by machining forces, allowing high-precision machining with a Swiss-type lathe.

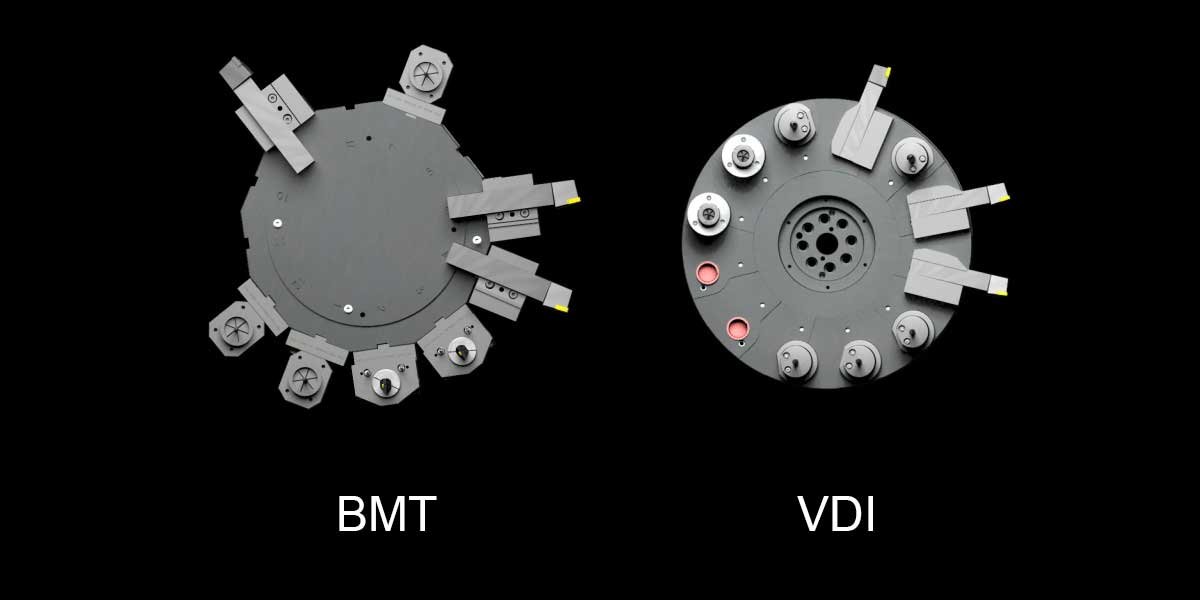

Differences Between BMT and VDI Turrets

In the field of CNC machine tools, BMT (Base Mount Turret) and VDI (Verband Deutscher Ingenieure) are two common types of turrets. They differ in terms of process, structure, precision, and operation, each suited to different machining needs. This article will provide a detailed comparison of these two turret types.

Classification of Gear Machining on CNC Lathes

Gear machining on CNC lathes is a crucial aspect of gear manufacturing, involving various machining methods and tools. Based on the machining method and the type of gear, CNC lathe gear machining can be primarily classified into: forming machining, gear hobbing, gear shaving, etc.

End Face Grooving

On CNC lathe, when machining end face grooves on the surface of a part, selecting the correct tool is crucial. The radius of the groove will determine the curvature of the tool. Since the groove is arc-shaped, chip removal can become an issue. Chips clogging the groove can lead to blade breakage, creating safety hazards.

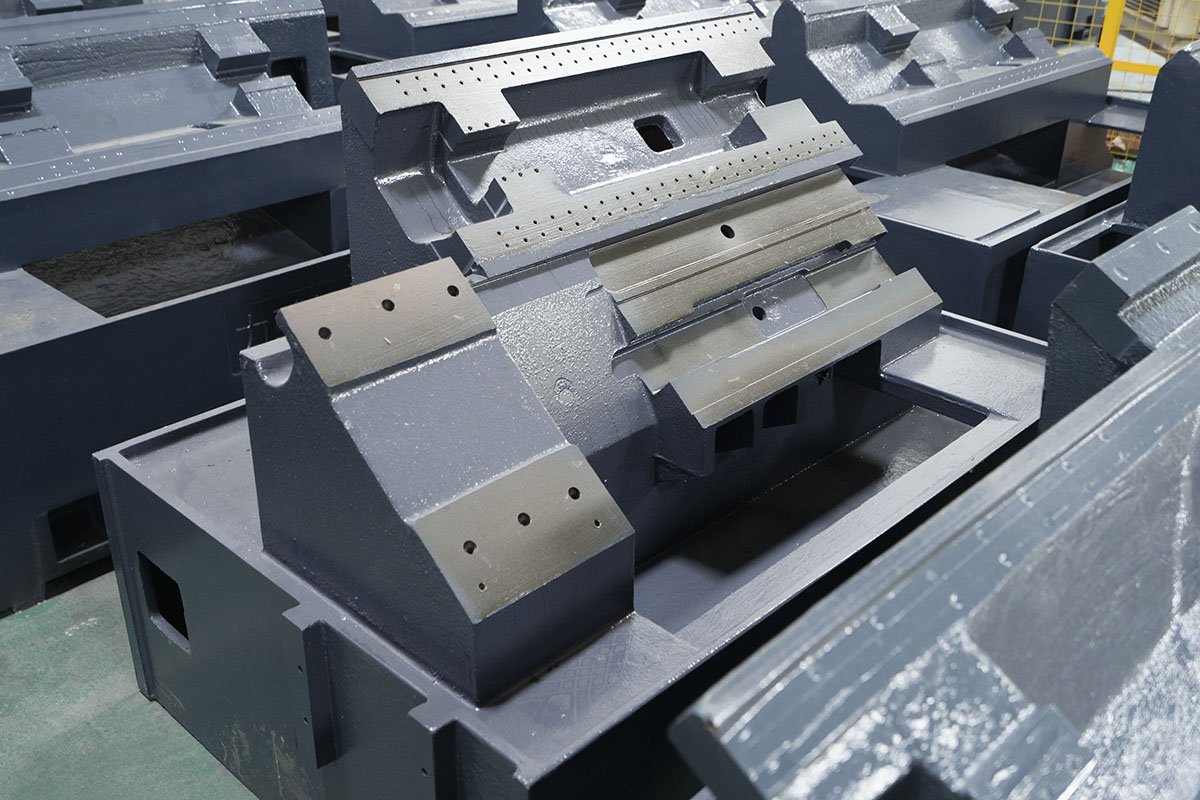

Vibration Damping Principle of Cast Iron

The material selection for the base of a CNC lathe is critical for ensuring the stability and precision of the machine. Commonly used materials for the base include cast iron, steel, and concrete. The base provides high rigidity and stability, absorbing vibrations during machining to ensure processing accuracy. The design of the base ensures the overall stability of the machine, reducing thermal and mechanical deformation, thus enhancing the machine's lifespan and machining quality.

Considering that CNC lathes prioritize stability and require strong vibration damping, cast iron is typically chosen for the base over steel. This is often achieved through integral molding, reducing the need for welding and assembly processes, lowering manufacturing costs, and improving production efficiency.

Calculation of Machining Time for Facing, Parting Off, and Deep Grooving on a CNC Lathe

SMARTLATHE often needs to calculate machining times during the analysis of CNC lathe drawings. While CNC programming software can typically complete these calculations quickly, it is important for us to understand how the software performs these calculations.

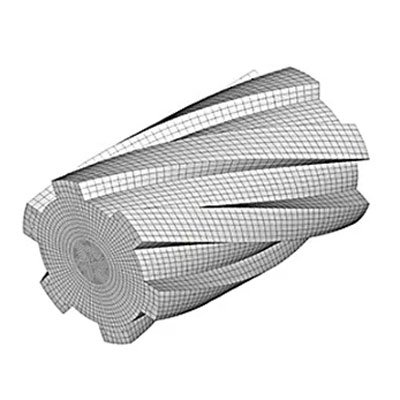

Comparison of Helical Splines and Straight Splines

1.1 Helical Splines

The spline teeth are helical, similar to threads. The tooth surface is at a helical angle, with a smaller tooth profile angle. The design is more complex, and the manufacturing difficulty is higher.

1.2 Straight Splines

The spline teeth are straight, parallel to the spline axis. The tooth surface is parallel to the axis, with a simple tooth profile. The design is relatively simple, and manufacturing is easier.

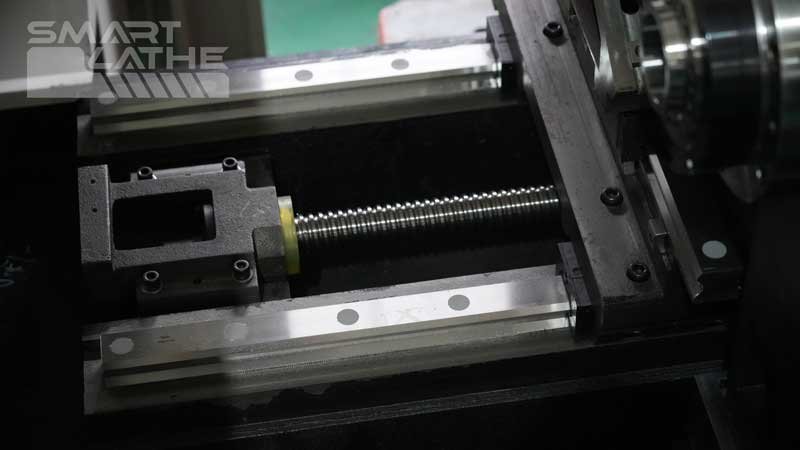

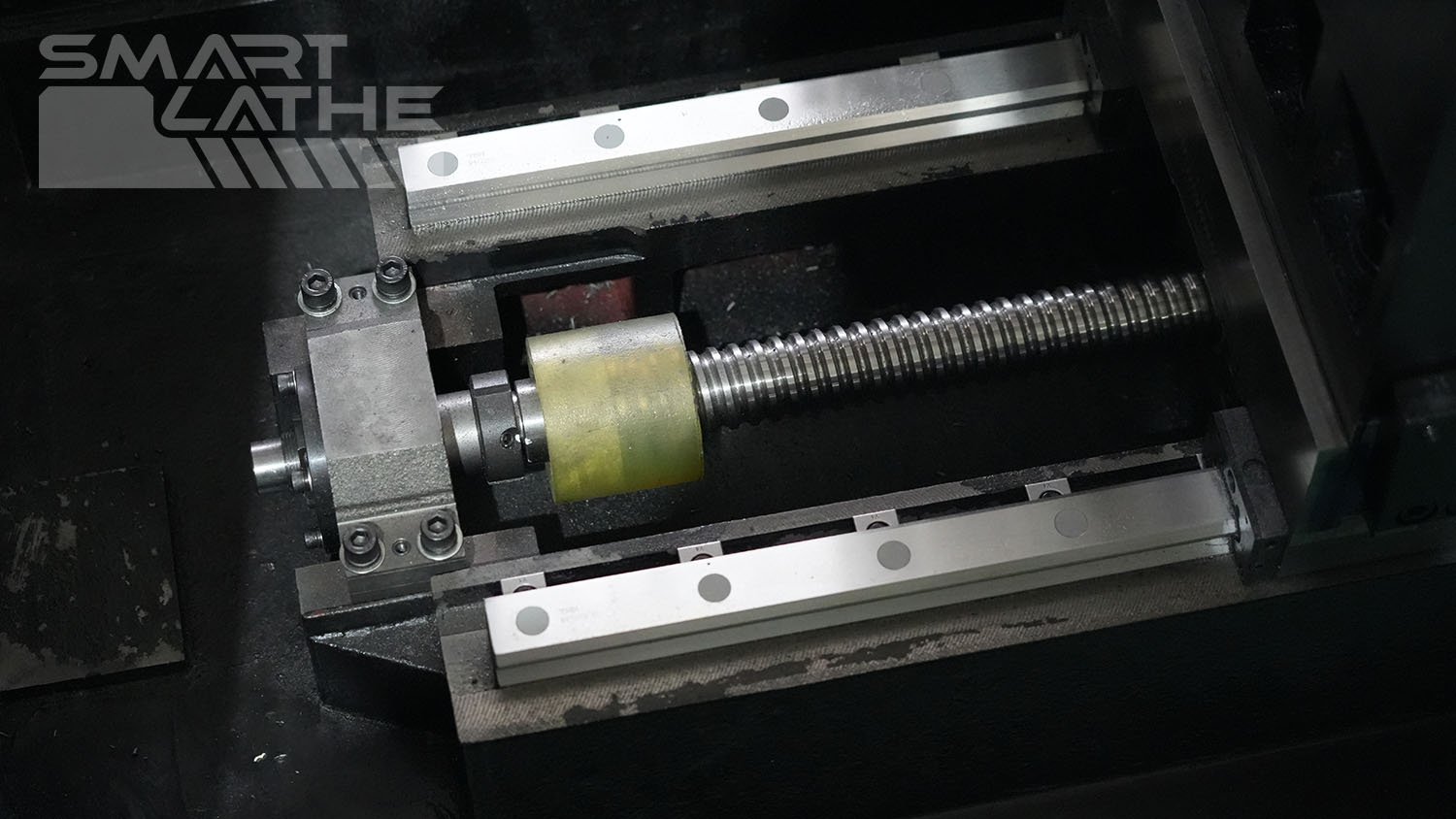

Classification of geometric tolerances during CNC lathe machining—Guide rails

The geometric tolerances of CNC lathe guide rails have a significant impact on machining accuracy and workpiece quality. These tolerances mainly include horizontal straightness tolerance, vertical straightness tolerance, and parallelism tolerance of the guide rails.

The Difference Between Positioning Accuracy and Repeatability in CNC Lathes

In CNC lathe operations, positioning accuracy and repeatability are two key parameters that directly affect machining quality and production efficiency. Understanding and correctly applying these concepts can help optimize the machining process and improve product quality. This article will detail these two concepts and their differences.

Selection of Threading Inserts for CNC Lathes

When performing threading on a CNC lathe, it is crucial to select the most suitable threading inserts for your application based on the insert type, flank/radial clearance, and insert profile. These factors significantly impact chip control, insert wear, tool life, and thread quality.

Adiabatic Shearing Phenomenon in High-Speed Cutting

In the field of precision manufacturing, high-speed cutting technology is highly regarded for its efficiency and precision. However, behind this technology lies a complex physical process known as the "adiabatic shearing phenomenon." So, what is the adiabatic shearing phenomenon in high-speed cutting? Today, let's unveil the mystery behind this technology.

Common issues and solutions for rigid tapping

During the tapping process, various issues can arise that affect production techniques and efficiency. Today, we will analyze the solutions to common tapping problems.

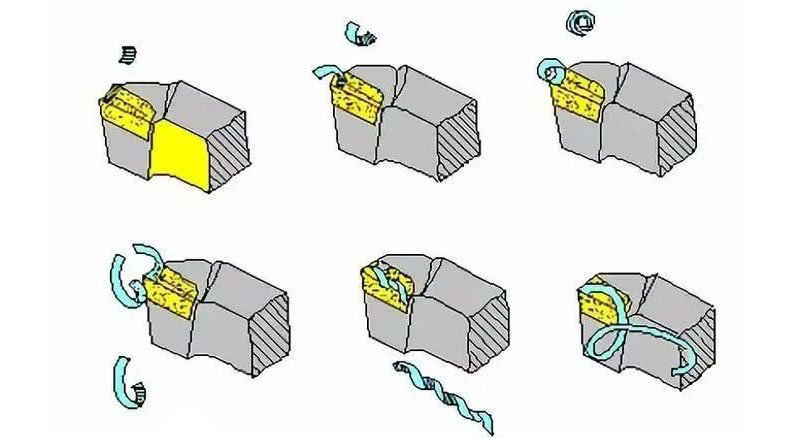

The Impact of Spindle Speed and Feed Rate on Chip Formation

In the world of CNC lathe, chip formation is a crucial indicator. It directly affects machining efficiency, tool life, and the quality of the finished product. When delving into chip formation, two critical factors come to the forefront: spindle speed and feed rate.

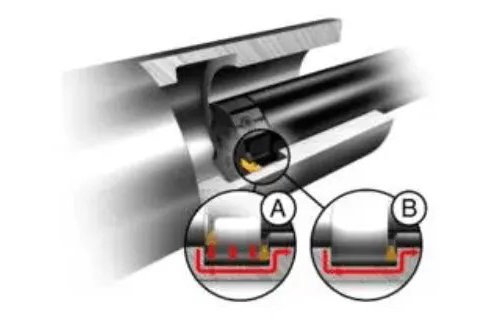

CNC Lathe Internal Grooving Process

The two main challenges in internal groove machining are excessive extension of the guide rod and poor chip removal. Excessive extension can lead to deflection and vibration issues. Vibration and poor chip removal can cause insert breakage. Difficulty in chip removal can also lead to poor surface finish. The most common internal groove machining process is radial grooving; however, multi-groove turning (A) and feed-in turning (B) can also be used.

Common Solutions for Tool Sticking on CNC Lathes for Various Materials

Tool sticking on CNC lathes refers to the phenomenon where the cutting tool adheres to the workpiece material during machining. This results in material buildup on the tool surface, affecting both the quality and efficiency of the machining process. To address this issue, it is essential to understand the properties of the materials and the causes of the phenomenon to provide suitable solutions.